Best technical Cleanliness for Additive Manufacturing

For a leading manufacturer of additively produced high-performance components, MAFAC demonstrates that even in this forward-looking sector, perfect cleaning results are achievable when paired with future-ready technologies

Exploring new grounds is our daily business. Every project brings new geometries, materials, and process conditions. What matters is embracing these challenges. To analyze, to develop and to test until the result is meeting the requirements. That’s how convincing solutions are created, that truly make a difference.

Lukas Baier, Head of Global Service & Industrial Solutions MAFAC

New Requirements for industrial Cleaning

In additive manufacturing, components differ fundamentally from those produced using conventional methods. While traditional processes are limited by tool geometries and machining steps, the various additive technologies largely remove these restrictions.

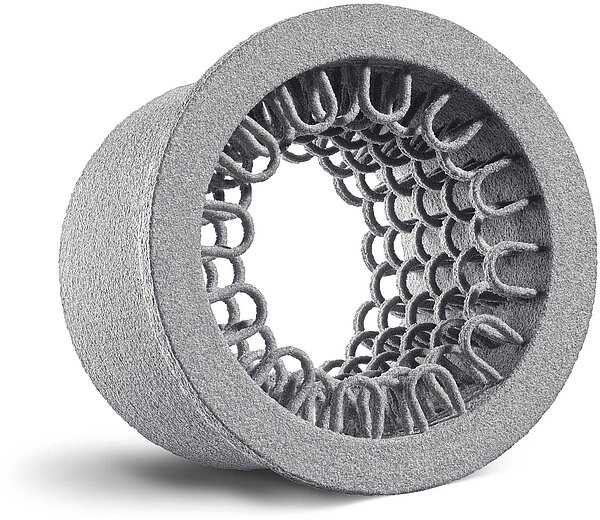

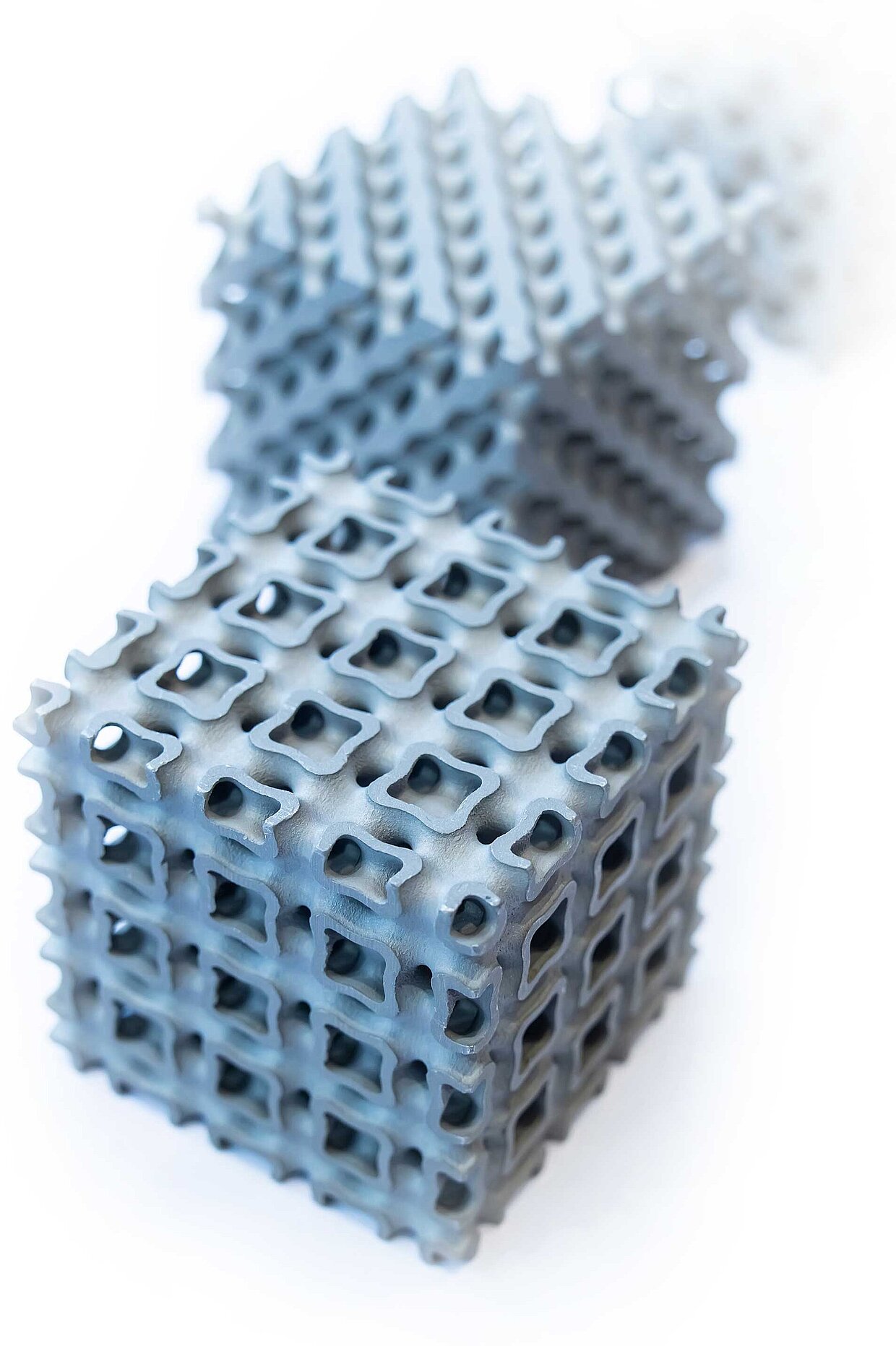

They enable extremely complex and delicate designs – bionic structures, internal lattice geometries, or multifunctional components. The result is lighter, stronger, and more efficient products that would be impossible to realize with traditional methods.

Yet with these new opportunities come new challenges. Powder residues, sintered deposits, and filmic contaminants settle deep within microstructures, adhere to surfaces, or accumulate in areas that are difficult to access. Conventional cleaning methods quickly reach their physical limits. Spray or immersion processes cannot fully reach internal cavities, while manual rework is error-prone and barely reproducible.

Especially in safety-critical applications or when components are subsequently coated, painted, or functionally finished, absolute cleanliness is essential. What has been missing so far is a stable, validated process that can be automated, documented, and integrated into quality assurance.

This was precisely the gap a leading manufacturer of additively produced high-performance components set out to close.

Automated deburring, cleaning, and drying in Additive Manufacturing with MAFAC Technologies

Additive Manufacturing with System – From Powder to Surface

The company ranks among the technological pioneers in industrial 3D printing and has continuously advanced its laser-based additive manufacturing process, known as Laser Powder Bed Fusion (LPBF). Its digital manufacturing infrastructure includes ten laser sintering systems, a dedicated research platform for 3D printing, a proprietary chemical smoothing process, and specialized areas for coating and painting.

The result: highly complex lightweight structures with internal media channels and functional interfaces – monolithic components that transcend the limits of conventional production. The materials used range from high-performance polymers such as PA12, PA11, or TPU to specialty materials with exceptional thermal and chemical properties.

Depending on the application, the printed parts are color-finished or optically refined before being precisely processed in post-treatment and assembly. This manufacturing depth is supported by a multi-stage quality assurance system that extends from powder management and the build process to surface finishing. Cleaning has become an increasingly critical stage in this process chain – one that until recently could not yet be seamlessly integrated into additive manufacturing.

From Analysis to the right Technologies

That cleaning within the additive process chain was still an open issue served as an incentive for MAFAC. From the outset, the company delved into the specific demands of additive manufacturing – from materials and part geometries to typical powder and post-processing residues.

Collaboration with the customer took place on equal footing. Together, they evaluated sample parts, identified critical areas, and compared different cleaning strategies. It quickly became clear that conventional systems could only meet the requirements of additive manufacturing to a limited extent. The key was to tailor the cleaning process precisely to geometry, material, and residue type – ensuring maximum process stability and reproducible cleanliness.

After extensive testing, MAFAC selected two of its in-house developed, patented technologies, supplemented by ultrasonic cleaning. With MAFAC Vectorkinematics, the basket and spray system rotate while the spray arm simultaneously performs swiveling motions. The constantly changing spray angles deliver a significantly higher cleaning effect compared with rigid systems.

During flooding, increased flow turbulence enhances the interaction between cleaning medium and surface. The motion of the nozzles also supports uniform and efficient drying in the subsequent process step. The MAFAC VAP (Vacuum Activated Purification) process adds another dimension: alternating vacuum and overpressure cycles in the cleaning bath generate dynamic flow patterns that reliably flush even the smallest channels and complex internal cavities.

All process parameters – pressure, temperature, media quality, and time – can be precisely controlled, stored, and, if necessary, adjusted for new geometries or materials. This ensures reproducible process quality and consistently high cleaning results.

In further test series using original parts, MAFAC validated the performance of the selected configuration. Different materials and geometries were analyzed, parameters fine-tuned, and results documented. The outcome is a stable, auditable cleaning process that integrates seamlessly into the customer’s digital manufacturing workflow – and demonstrates the potential created when additive manufacturing meets innovative cleaning technology.

As a pioneer in additive manufacturing, we constantly evolve our technologies and processes – even in areas where no standards exist yet. Industrial cleaning was one of those challenges. With openness and precision MAFAC handled this topic in the same way as we understand innovation. The result is impressive – both technically and in terms of partnership.

Customer's Feedback

The Results – clean Performance, new Perspectives

The result speaks for itself: internal structures and complex geometries of 3D-printed products and components can now be cleaned reproducibly and with full material protection. There is no need for manual rework, inspection effort is reduced, and the cycle times are significantly shorter. The additive manufacturing process chain is now fully closed for the first time.

MAFAC also draws a positive conclusion. The project provides valuable insights for future applications and demonstrates how flexibly the company’s technologies and expertise can be transferred to new industries. At MAFAC, there are no standard solutions.

Every task calls for a customized combination of cleaning system, process, and application design.

Has this article sparked your interest and would you like to know how your innovative products can also be cleaned safely and in a future-proof way?

Get in touch with us for tailored advice.

Request Consultation now