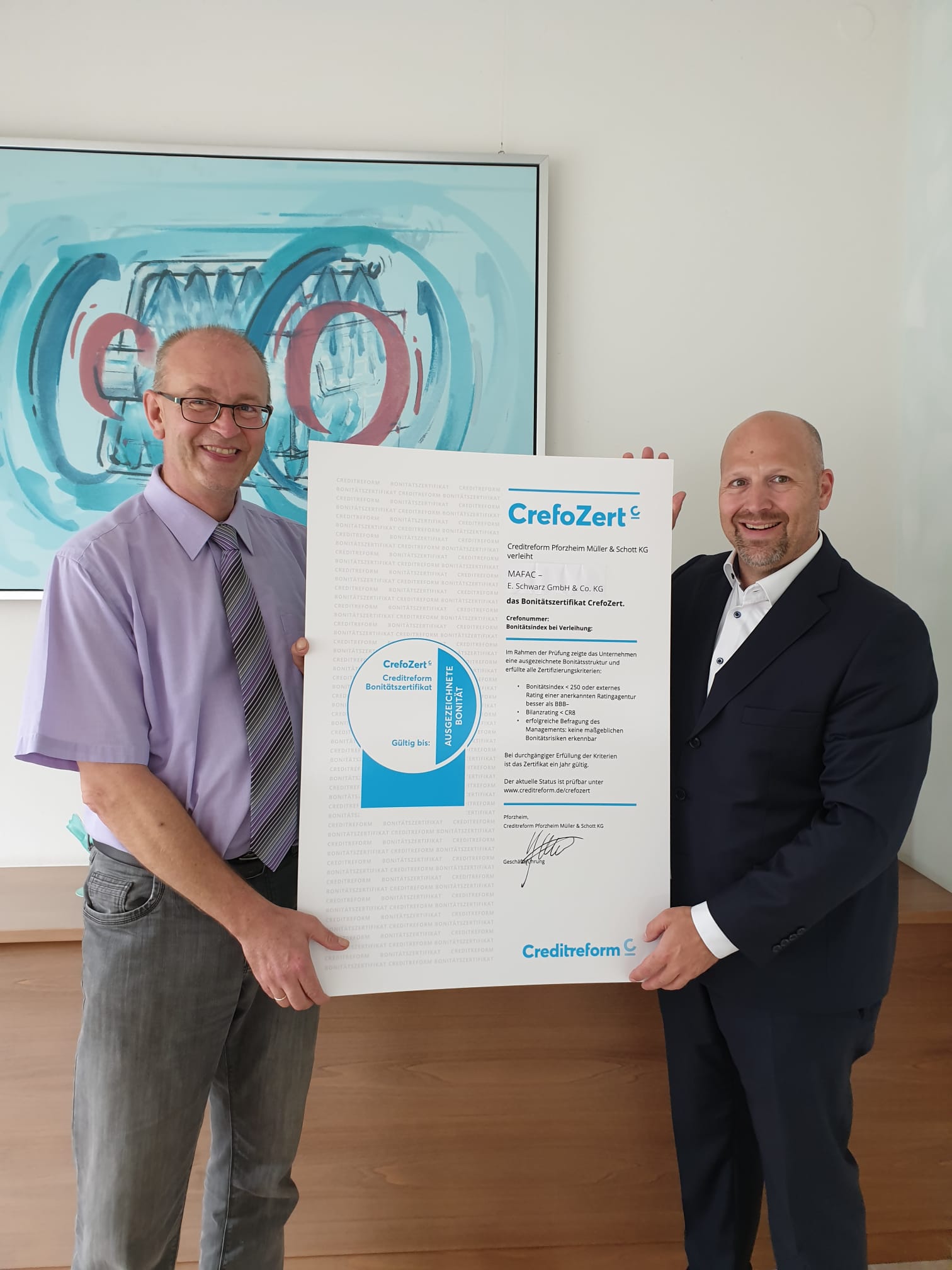

Website growing

Our new website is developing nicely – you can look forward to it! To a fresh, clean look. To detailed informations with just a few clicks, the MAFAC magazine and much more.

Just a few weeks to wait now!

Would you like to be informed about the Launch?

Then register now to our newsletter and we‘ll keep you up to date. (Subscription can be cancelled at any time)