MAFAC Kinematics: Technology for Cleaning and Drying – efficient with Rotation

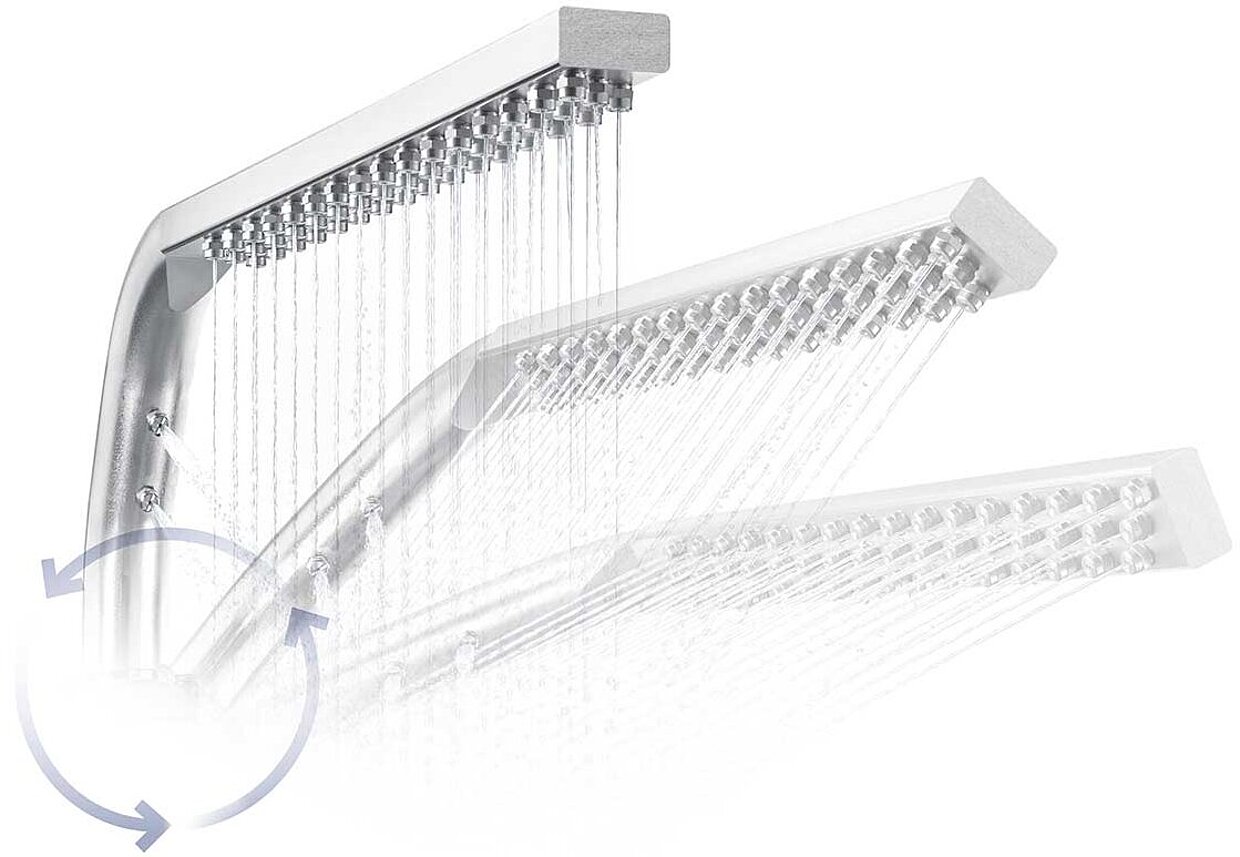

Using motion intelligently defines MAFAC Kinematics, our patented process for aqueous component cleaning. By rotating the cleaning basket and spray system simultaneously, we create a highly dynamic impact on the component surfaces.

Unlike conventional systems, where either the basket or the spray arm rotates, MAFAC Kinematics synchronizes both components. This process-controlled rotation, in co-rotating or counter-rotating mode, generates targeted flow turbulences. The cleaning medium impacts your components from constantly changing directions with consistent intensity, reliably removing contamination even from complex geometries.

The high mechanical impulse exchange also improves heat and material transport. As a result, cleaning with MAFAC Kinematics is faster, delivers improved results, and can be carried out at reduced process temperatures.

Technical Highlights for your Process

| • Intelligent rotation: The cleaning basket and spray system move simultaneously and in precise coordination. |

| • Optimized flow dynamics: Controlled turbulences and varying impact angles measurably increase cleaning performance. |

| • Flexibly adjustable process parameters: Rotational speeds can be precisely set to achieve the required level of cleanliness. |

| • Process-reliable drying: Rotation optimizes heat transfer, allowing components to dry more evenly with lower residual moisture. |

Your Advantages with MAFAC Kinematics

| • Patented MAFAC technology |

| • Higher cleaning performance through dynamic impact |

| • Shorter process times through optimized media utilization |

| • Uniform drying, even for complex components |

The Operating Principle of MAFAC Kinematics

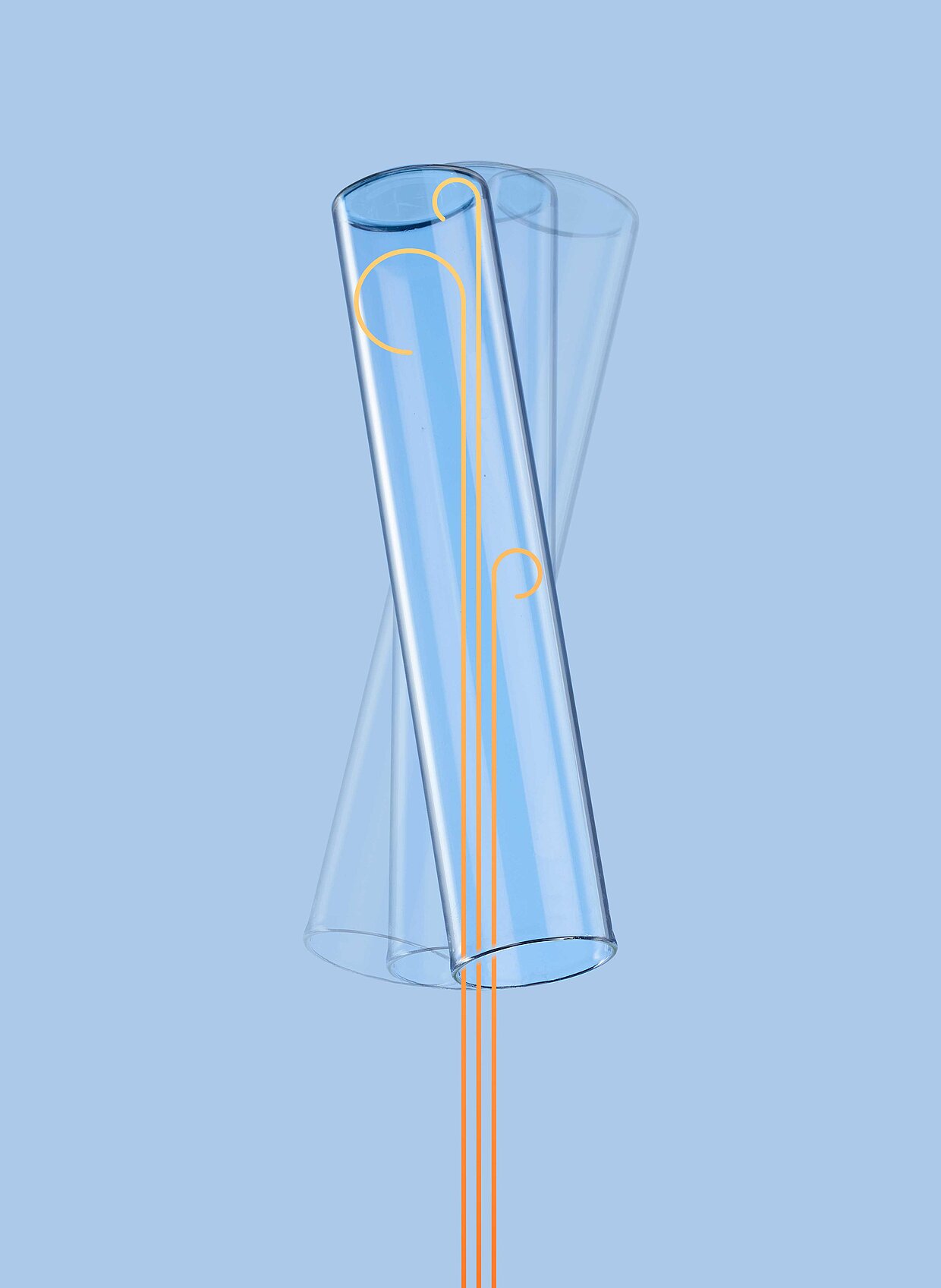

Static system: Reduced impulse force

Imagine cleaning a stationary container with water from a hose.

What happens?

At first, the jet hits the surface with full force and removes contamination.

As the water level rises, the impulse force decreases – and with it the cleaning effect.

MAFAC Kinematics: Motion is the key

The spray system rotates while the basket with the components to be cleaned rotates simultaneously.

This precisely controlled motion creates turbulence and high cleaning efficiency.

The cleaning medium reaches your products everywhere, from all angles with consistent force.

Rotation: for targeted drying

Rotation also improves drying performance by reducing cycle times and increasing efficiency.

Your components are optimally prepared for subsequent production steps.

The drying level can be individually controlled – up to completely dry and free of residual moisture.

MAFAC Kinematik im Video

MAFAC Kinematik FAQs

What are the advantages of MAFAC Kinematics?

MAFAC Kinematics is a universally applicable technology that delivers high cleaning quality, short process times, and efficient, uniform drying.

For which applications and industries is MAFAC Kinematics suitable?

MAFAC Kinematics is a versatile cleaning and drying solution for a wide range of applications – including the automotive industry, medical technology, and metalworking. Components made of plastics and composite materials can also be cleaned and dried reliably.

Can MAFAC Kinematics be combined with other cleaning technologies?

Yes. MAFAC Kinematics can be combined with other MAFAC cleaning technologies in an application-oriented manner – including MAFAC Vectorkinematics, the MAFAC VAP pressure change process, and/or rotating ultrasonics. This allows the cleaning performance to be precisely tailored to component types and industry requirements. You benefit from high flexibility, process reliability, and consolidated MAFAC expertise from a single source.