Highly flexible Cleaning Solutions for Additive Manufacturing

New freedoms. New challenges.

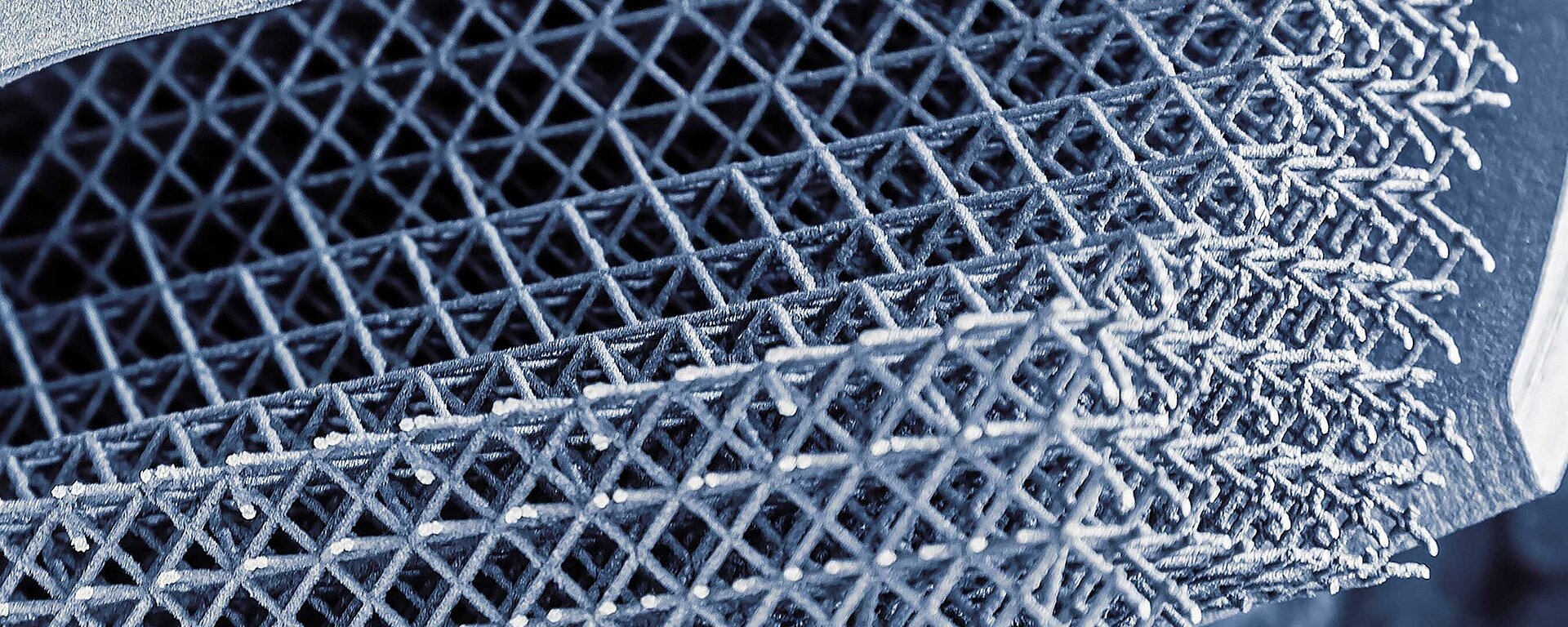

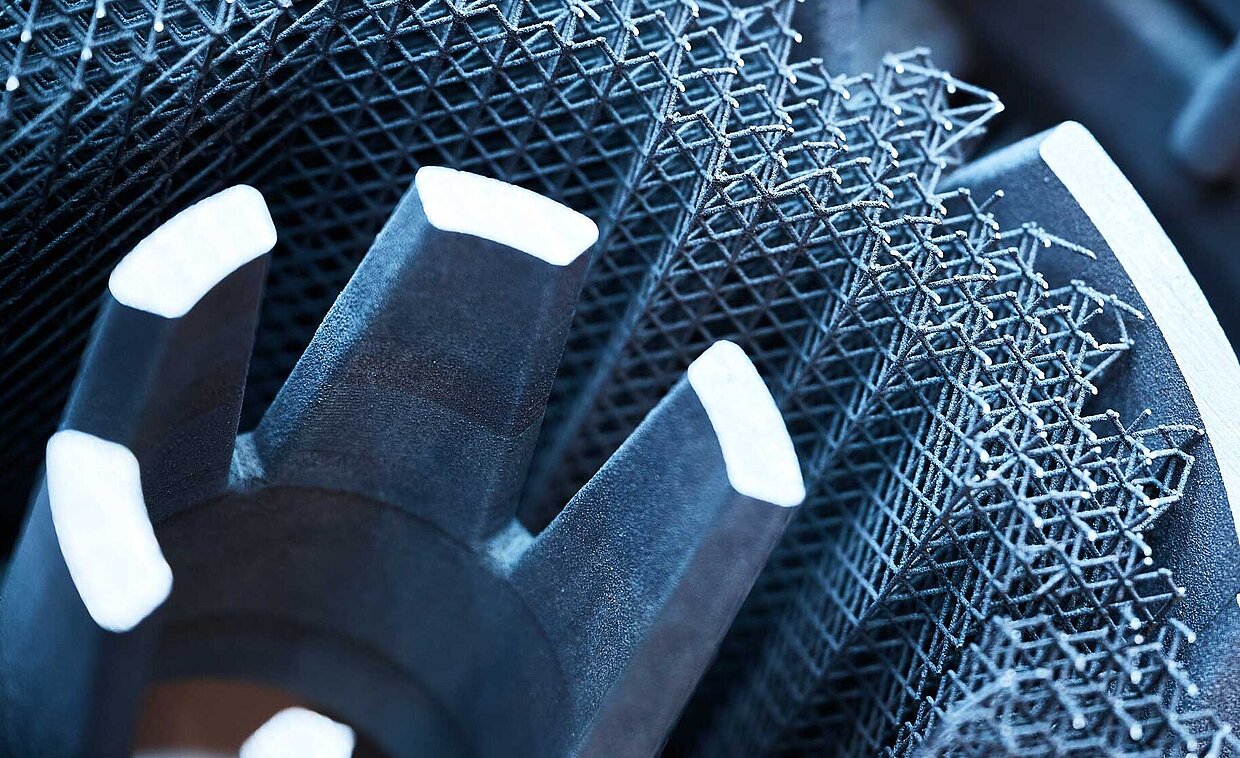

Innovative 3D-printed components open up new freedoms in terms of geometry, materiality, and function.

And they require cleaning that can handle this complexity – from bionic structures to challenging internal contours.

MAFAC develops this process for you: water-based, variable, and with patented technologies.

For reproducible cleanliness and secure integration into your AM process chain.

Understanding processes. Designing cleanliness.

Additive manufacturing enables components that were previously inconceivable – functionally integrated, built layer by layer, using new materials and often significantly more complex than conventionally manufactured parts. This creates a production reality that cannot be achieved with conventional cleaning methods. This new world requires a partner who is prepared to develop suitable solutions rather than adapting outdated cleanliness concepts.

MAFAC meets precisely this requirement. Our water-based technologies can be precisely tailored to the specific characteristics of additive components, and the cleaning and drying process can be seamlessly integrated into digital manufacturing environments. Developed to fit perfectly for the reproducible cleanliness of your parts and components in the highly dynamic market of additive manufacturing.

Case study: validatable MAFAC cleaning solution for additively manufactured high-performance components

Read here how MAFAC technologies were used to implement an automated and validatable cleaning process for depowdering, cleaning, and drying of additively manufactured high-performance components.

read Article

Your benefits with MAFAC technologies for additive manufacturing processes

- Completely remove residues from additive processes. For example, powder or deposits from binder, extrusion, or laser processes—even in deep channels and lattice structures.

- Reliably clean surfaces with variable roughness. For example, porous, topology-optimized, or additively manufactured functional surfaces.

- Master geometric complexity with confidence. With stable results in internal contours, microchannels, and functional cavities.

- Provide stable support for AM process chains. From debinding and removal of support residues to component handling and downstream manufacturing steps.

- Ensure validatable and audit-proof process control – as needed. With fully documented and verifiable parameters.

- Reliably achieve the desired degree of dryness. Until absolutely dry and ready for subsequent processes and logistics.

Verifying Cleanliness. Aligned with Target Industry Standards.

3D-printed components must meet the requirements of your target industries. Our cleaning solutions are precisely aligned with the relevant standards as well as with your internal and customer-specific requirements – and achieve these standards reliably and reproducibly.

On request, we can integrate your internal test procedures and document the required level of cleanliness.

| Target area | Standards and Requirements |

|---|---|

| General AM requirements | Limits for powder, particulate, and process residues per customer specification; requirements for coating, heat treatment, sealing integrity, and functionalization |

| Aerospace | EN 9100 / AS 9100, Nadcap AC7108 / AC7101, OEM specifications, requirements for functional surfaces and coating capability |

| Automotive | VDA 19 / VDA 19.2, ISO 16232, OEM specifications, requirements for assembly cleanliness and process cleanliness |

| Medical Technology | ISO 10993, ISO 19227, ISO 13485, documented cleanliness for biocompatible applications |

| Microelectronics / Microsystems | IPC standards (e.g. IPC-A-610), ISO 14644 cleanroom requirement; standards for surface cleanliness and contact-critical microfeatures |

| Tooling / Mold Making | Requirements for functional tool surfaces, coating readiness, polishing and texturing specifications |

| Energy / Turbomachinery | Material- and process-specific requirements for high-performance alloys, documented functional surfaces |

Learn more – additional pages on this topic

Applications

Whether dental technology, aviation components, tools, or functionally integrated lightweight structures – we ensure cleanliness in your AM applications.

>> see Application Examples

Technology and Process Expertise

Reproducible cleanliness comes from the right process: based on our patented technologies. Precisely tailored to your target application.

>> see Cleaning Technologies

Additive Processes at a Glance

An overview of the most common manufacturing processes in additive manufacturing – including materials, energy sources, and areas of application.

>> see Glossary

FAQ Additive Manufacturing. Your Questions, our Answers.

How can powder and process residues be reliably removed from complex AM geometries?

Powder and process residues are removed through the coordinated interaction of spray, spray-flood and flood processes combined with kinematic motion of parts and the resulting turbulence. Ultrasonics and the MAFAC VAP pressure-change technology also reach deep internal structures, ensuring a reproducible cleaning effect.

Which cleaning processes are suitable for bionic structures, internal channels, and lattice-like regions?

For complex internal geometries, we rely on the combination of MAFAC VAP and ultrasonics, as both technologies act deeply within fine structural details. Directed flow and pressure variation allow residues to be removed reliably, delivering stable, reproducible cleaning performance also in bionic contours and lattice-like areas.

What role does material diversity in AM – metals, polymers, hybrid structures – play in process design?

Metals, polymers and hybrid structures differ in density, porosity, surface energy and residue types. All of these factors influence process design. A precisely aligned strategy involving mechanical action, cleaning media and temperature ensures that cleaning remains reproducible across materials while protecting sensitive surfaces.

How does MAFAC design water-based cleaning for components with variable roughness and porous surfaces?

Defined process windows ensure stable results even on rough or open-porous surfaces. Combined spray and flood processes together with kinematic motion provide targeted flow into complex regions. Ultrasound and, where required, MAFAC VAP support controlled ingress and egress of the medium into pores and micro-roughness.

Which residues from additive processes are critical for downstream steps such as heat treatment or coating?

Residual powder, embedded particles, partially sintered deposits and filmic contamination are particularly critical, as they affect wetting, adhesion and overall process stability. A targeted and reproducible cleaning process is therefore essential to ensure downstream steps run reliably and meet quality requirements.

How does MAFAC integrate cleaning into digital AM production environments and automated process chains?

MAFAC integrates cleaning seamlessly into your automation and MES structures via standardized interfaces. Process parameters and quality data are digitally traceable and can be monitored inline. Through digital monitoring, stable process profiles and robot-assisted material flow, a fully connected, Industry-4.0-ready process chain is created.

Are MAFAC cleaning processes validatable and audit-ready when target industries require corresponding proof?

Yes. MAFAC cleaning processes can be operated in a validatable and audit-ready manner when your target industries require documented proof. Clear parameter control, reproducible process sequences and complete documentation provide a solid basis for meeting industry-specific cleanliness and quality requirements.

How is stable and reproducible cleaning ensured across different geometries and production series?

Stable, repeatable results arise from defined mechanical principles, precise kinematics and clearly defined parameter windows. Spray, flood and ultrasonic processes, together with MAFAC VAP, interact in a controlled manner to deliver consistent cleaning performance regardless of geometry variations or batch fluctuations.

What options exist for targeted drying of complex internal structures and porous areas?

Warm airflows and pulse blowing support targeted drying of hard-to-reach areas. Vacuum drying is particularly effective in internal cavities and porous zones. With precise kinematics, a reproducible drying performance is achieved – mirroring the stability and reliability of the cleaning process for demanding AM geometries.

Can test cleanings be performed with original AM components to validate strategy and process design?

Yes. Test cleanings with your original AM components enable a reliable assessment of geometry, powder behavior and residue types. Based on these insights, we develop a robust process strategy with suitable technologies and parameters – providing a dependable foundation for future series production.