Validatable Cleaning in Medical Technology

Efficient, reproducible, future-proof.

You distribute or manufacture medical technology products and components that must be cleaned across all production steps in a manner that is documented and MDR-compliant.

MAFAC designs a cleaning process for this purpose that integrates seamlessly, reliably removes all typical types of contamination –

from film to bioburden – and can be precisely adapted to new specifications or variants.

Cleaning as an integral part of your production process

Understanding processes. Designing cleanliness.

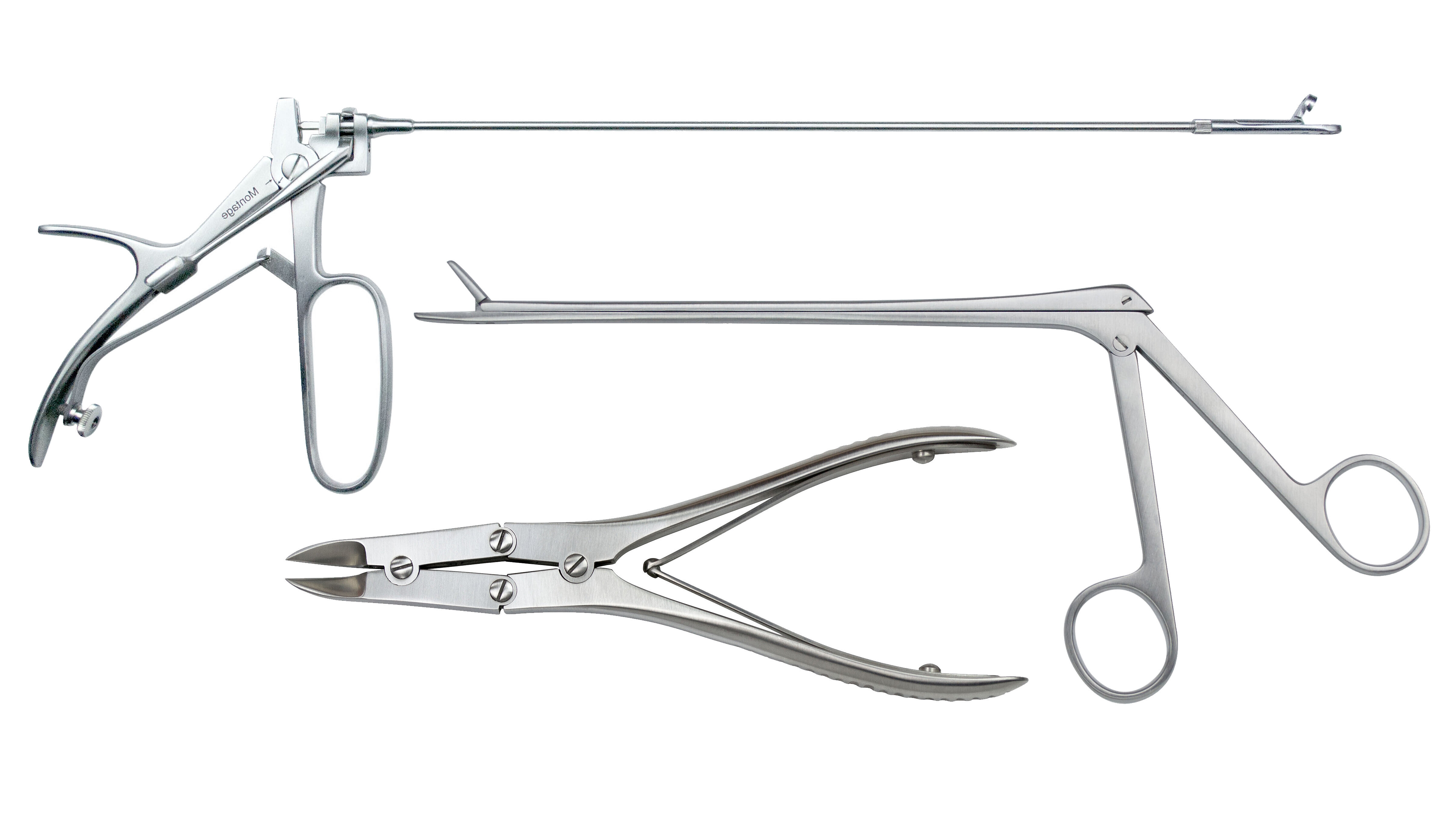

Medical technology requires processes that ensure the highest quality at every step. This applies to your entire production process – and therefore also to cleaning. Whether pre-cleaning after mechanical processing, intermediate cleaning as a basis for subsequent steps such as coating, or final cleaning with complete drying: MAFAC develops the right cleaning solution.

To do this, we bring our expertise in demanding industries and sensitive applications to bear right from the start.

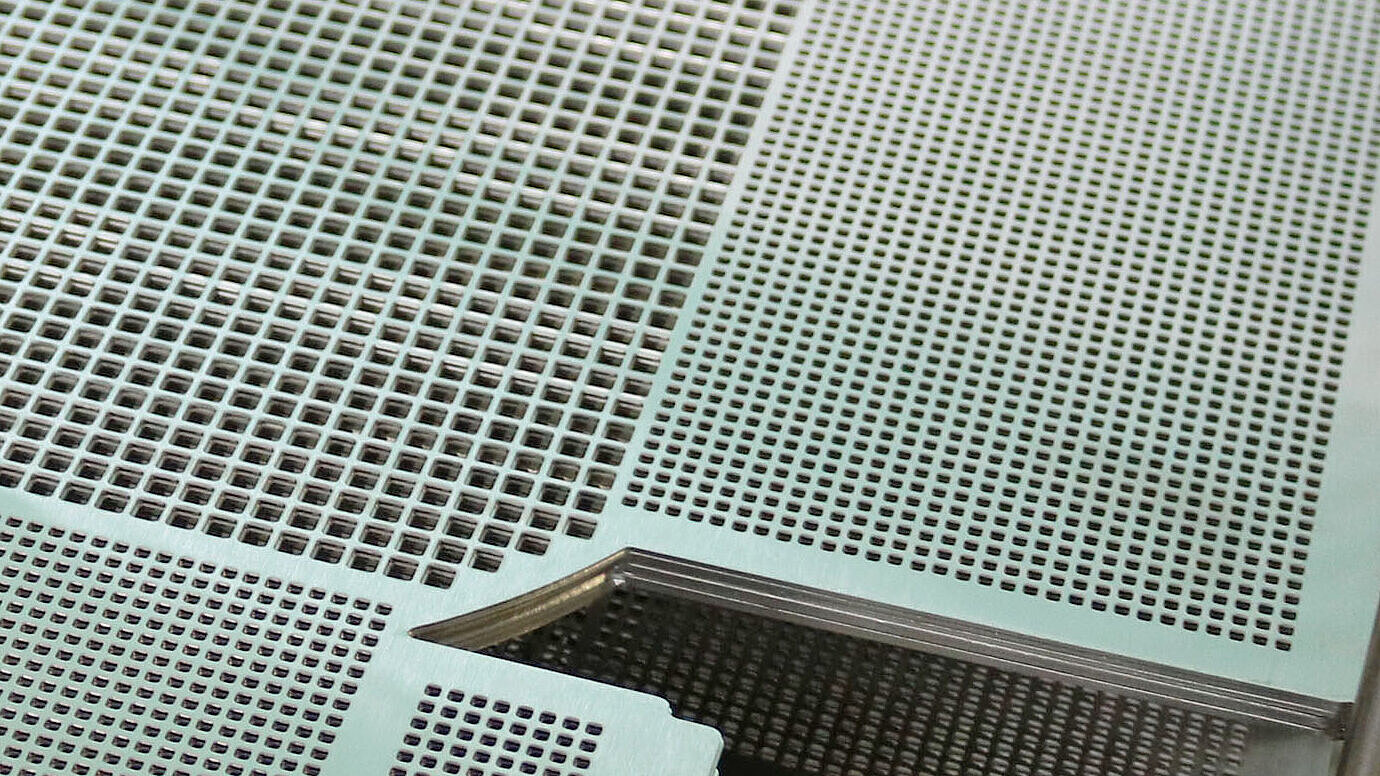

We analyze your components, identify typical contaminants, and define the cleaning strategy. Based on this – and using other criteria such as quantities, standards catalog, and required performance – we select the appropriate cleaning system from our portfolio and the right combination of our patented technologies.

The result is a process that achieves reproducible technical cleanliness and fits precisely into your production structure—today and for new tasks.

Case study: MAFAC cleaning solution for sensitive medtech products across multiple series

Read here how process expertise and technologies from MAFAC were used to implement a cleaning process for customer-specific medtech products – cross-series and fully validatable.

Read Article

Your benefits with MAFAC technologies for medtech processes

- Safely clean complex geometries. With deep penetration into lumens, capillaries, and shaded areas.

- Ensure audit-proof and validatable process control. With fully documented and verifiable parameters.

- Safely manage variants, quantities, and new products. With consistent results across component changes and series.

- Achieve targeted drying. Absolutely dry on surfaces and in internal structures, ready for subsequent processes and logistics.

- Ensure the quality of subsequent processes. Technical cleanliness for coating, assembly, sterilization, or packaging.

- Maintain purity in accordance with common standards. For example, according to VDA 19, ISO 16232, or ISO 10993.

Verifying cleanliness. In line with the standards of your industry.

Medical products must meet strict cleanliness standards. Our cleaning solutions are precisely tailored to the relevant standards as well as internal and customer-specific requirements – and achieve these standards reliably and reproducibly.

On request, we can integrate your internal test procedures and document the required level of cleanliness.

| Residues | Standards |

|---|---|

| Particulate residues | VDA 19, ISO 16232, ASTM F2459-12 |

| Filmic residues | ISO 10993-18, USP <643>, ASTM F2847-10 |

| Organic residues (TOC/THC) | ISO 10993-18, USP <643>, ASTM F2847-10 |

| Cytotoxicity | DIN EN ISO 10993-5, USP 87 |

| Bioburden | ISO 11737-1 |

| Endotoxins | DIN EN ISO 11737-3, USP <85> |

| Ionic residues | ISO 7888, USP <645> |

Learn more – additional pages on this topic

Applications

From A for abutments to I for implants zo Z for Zimmer splints – we ensure highest technical cleanliness for your medtech products.

>> see Application Examples

Technology and process expertise

Reproducible cleanliness is achieved through the right process: based on our patented technologies and precisely tailored to your target application.

>> see Cleaning Technologies

Even more insights – MAFAC user reports on medical technology

FAQ Medical Technology. Your Questions, our Answers.

Can the cleaning process be validated in accordance with MDR?

Yes, of course. Reproducible processes and measurable parameters are prerequisites for validation. We document all variables—pressure, temperature, media quality, and time. The parameters are defined in test cleanings, and several batches prove stability. The process is traceable and auditable in accordance with MDR and ISO 13485; if necessary, we will work with you to create the requirements matrix.

What role does geometry play in the cleanability of medical components?

Lumen, cavities, and capillary structures are difficult to access and therefore particularly critical. Shaded areas are best reached with directed flow and pressure changes. Even delicate mechanisms such as joints or springs harbor residual dirt risks; internal channels—for example, in endoscopy—are typical problem areas. MAFAC Vektorkinematik and MAFAC VAP are designed for complex geometries and reliably remove film-like and particulate residues.

Can MAFAC also integrate customer-specific testing procedures?

Yes. We integrate particulate residue analyses directly into the process. Tests such as TOC, cytotoxicity, or chemical analyses are performed downstream outside the plant. Our processes can be tailored to OEM-specific requirements as well as standards such as VDA 19, ISO 16232, or ISO 10993-18.

What are the advantages of combining the MAFAC VAP pressure change process with rotating ultrasound?

The MAFAC VAP pressure alternation process acts deep within lumens and capillaries, while rotating ultrasound generates comprehensive cavitation. This combination reliably reaches complex internal areas and safely removes particles such as film-like residues. This ensures high cleaning quality even for demanding components, such as those used in surgery and endoscopy.

Does MAFAC also comply with corporate standards and specifications?

Yes. We tailor processes beyond general regulations to company-specific limit values and test methods, and programs for each component are stored in the system in a reproducible manner. Freely definable parameters allow for individual specifications; documentation and validation are also possible in line with your internal QA structures.