MAFAC Vectorkinematics: Cleaning and Drying Components – combining Rotation and Swiveling

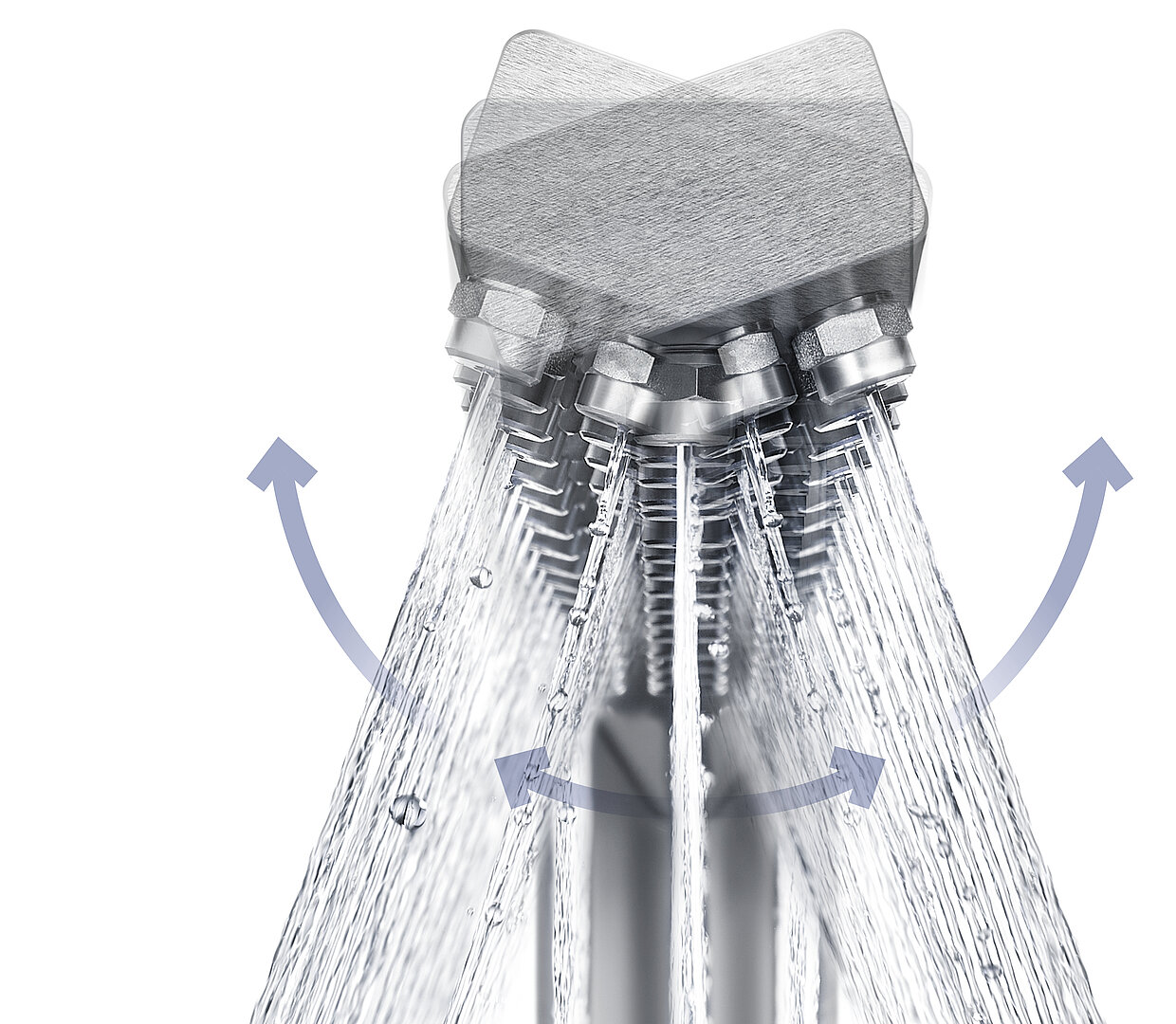

Motion, optimized. With MAFAC Vectorkinematics, our patented extension of MAFAC Kinematics, we add a third axis of motion to the rotation of the cleaning basket and spray system: the targeted swiveling of the spray nozzle to create varying impact angles.

During the process, the spray system continuously changes its orientation. The water jet strikes the components from different directions. This angle variation – in combination with the MAFAC-typical rotation – generates stronger turbulences and a highly dynamic media distribution. As a result, even hard-to-reach areas such as undercuts, blind holes, or complex geometries are cleaned reliably and free of residue.

An intelligently controlled motion pattern keeps the nozzle movement optimally aligned with the process at all times. The result is a significantly improved cleaning performance combined with reduced cycle times.

Technical Highlights for your Process

| • Intelligent rotation: The cleaning basket and spray system move simultaneously and in precise coordination. |

| • Additional axis of motion: The spray system swivels in a targeted manner to create variable impact angles of the water jet. |

| • Multidimensional flow: Targeted directional superposition allows the cleaning medium to act with maximum effectiveness. |

| • Adaptive process optimization: The movement of the spray nozzle is controlled algorithmically. |

| • Higher turbulence: Particles are intensively removed, even from hard-to-reach areas. |

| • Shorter cycle times: More efficient media guidance enables faster cleaning. |

Your Advantages with MAFAC Vectorkinematics

| • Patented MAFAC technology |

| • High cleaning effectiveness through targeted media guidance |

| • Reduced process times thanks to efficient use of cleaning media |

| • Effective cleaning of intricate and shaded areas |

| • Reproducible cleanliness for complex geometries |

| • Universal cleaning technology for different materials and industries |

Do your products and components have complex geometries? This is where conventional cleaning methods with fixed nozzles reach their limits. Some areas cannot be reached at all, or only partially, even with longer process times. At the same time, exposed surfaces may be over-cleaned and potentially damaged. MAFAC Vectorkinematics takes a different approach: With our patented technology, both simple and demanding components can be cleaned on a single system using suitable programs – delivering significantly higher effectiveness already during spray cleaning.

MAFAC Vectorkinematics: the next dimension of cleaning in motion. The technology combines the rotation of the cleaning basket and spray system with additional swiveling of the spray nozzle. Water and additives impact the components from constantly changing angles, resulting in a significantly higher cleaning effect compared to fixed systems.

Rotation and swiveling: efficient cleaning and drying. Thanks to angle variation and targeted turbulence, the cleaning medium reliably reaches undercuts, blind holes, and concealed areas. Filmic and particulate contaminants are removed faster and more thoroughly in a material-friendly manner; surfaces are left virtually free of particles. Flood cleaning is intensified by the increased turbulence. In addition, the moving nozzles support fast and uniform drying of the components.

MAFAC Vectorkinematics FAQs

What advantages does MAFAC Vectorkinematics offer for industrial parts cleaning?

MAFAC Vectorkinematics enhances the cleaning effectiveness of MAFAC Kinematics and allows for shorter cycle times while maintaining high process reliability. The key factor is the multidimensional movement of the cleaning medium with increased turbulence.

How does MAFAC Vectorkinematics affect cycle times in series production?

MAFAC Vectorkinematics significantly increases cleaning effectiveness per unit of time by dynamic movement of the spray system. By impacting the components from changing angles, particles are removed more quickly and the cleaning medium is used more efficiently. In series production, this results in shorter cycle times, higher throughput, and consistently high cleaning quality – even for complex components with demanding geometries.

How does variable impact on surfaces influence the removal of contaminants?

The variable impact of MAFAC Vectorkinematics creates changing flow directions and localized turbulence that act directly on the component surface. As a result, adhering contaminants are not only loosened mechanically, but also actively carried away from the surface by the dynamic movement of the cleaning medium.

Is MAFAC Vectorkinematics an established process in industrial parts cleaning?

MAFAC Vectorkinematics is an independent, patented process that has proven itself in daily industrial use across a wide range of industries. The technology is designed to work in close interaction with MAFAC cleaning systems and sets new standards compared to conventional systems in terms of cleaning performance and process flexibility.