Cleaning surgical Instruments – introducing an all-new Process

By introducing a completely new cleaning process, Gebrüder Zepf Medizintechnik is increasing quality and efficiency.

Precision in Medical Technology – Where Cleaning Defines the Outcome

Markus Lutter, head of workshop and production at Gebrüder Zepf Medizintechnik, had been aware for a long time that the previous process was no longer economical: the personnel costs too high, the process with manual switching from one basin to the next too complex. Especially since more and more instruments receive a wear-resistant coating after production.

For Markus Lutter and authorized signatory Markus Lippoth the time to act had come when tests with a more thorough pre-cleaning of the stainless steel components after machining led directly to better coating results.

A “wow” experience and the reason to completely redesign the cleaning process. It had to be compact, easy to use and flexible for a wide range of products.

And it had to deliver the best reproducible results.

Managing Director Tobias Zepf explains: “Cleaning plays a crucial role both in terms of our own quality standards as well as for the compliance of our entire process chain with European Medical Devices Regulation requirements.

Since 2020, our products are classified in the higher risk class Ir for reprocessable surgical instruments. This entails increased requirements that did not exist before.”

Re-shaping our cleaning process was exactly the right decision. With the MAFAC JAVA, we are excellenty prepared in the long term and can meet increasing demands on process reliability.

Tobias Zepf, Managing Director

MAFAC JAVA keeps the Flow going

In order to meet the above-mentioned requirements and to ensure continuous production, Gebrüder Zepf Medizintechnik decided for a MAFAC JAVA .

On the one hand, the rotation of the basket holder and the spraying system allows gentle, highly efficient cleaning of the premium instruments. On the other hand, according to Markus Lutter, “now all steps run compactly and reliably in one system. The MAFAC JAVA is integrated into the production process in a space-saving manner and is so variable that we are excellenty prepared for the future.”

According to Thomas Gutmann, Head of Customer Support at MAFAC, this variability makes the difference not only in sensitive medical technology, but in all user industries:

“Water-based cleaning with our patented cleaning and drying technologies offers a wide range of parameters that can be set individually and precisely according to the respective specifications. The programs already stored can be adapted accordingly or supplemented with additional ones – for a change of material, a new component, a more complex geometry.”

For intermediate and final cleaning, Gebrüder Zepf Medizintechnik currently runs three programs, each of a duration of about 20 minutes. In the cleaning phase, the stainless steel components mounted in a tool carrier are cleaned in a sequence of spraying, spray flooding and renewed spraying, the dirt particles are loosened and removed from the process.

The components are blown off before rinsing. This lifting process prevents the cleaning medium from being carried to tank two, which is filled with pure water for rinsing.

I’m absolutely thrilled how precisely the cleaning process can be customized to fit our demands and how water-based parts cleaning can offer such significant possibilities.

Markus Lutter, Head of Workshop and Production

The Cleaning Process - tested and optimized

To achieve absolute dryness prior to packaging or further processing – coating the components and spraying the handles with silicone – the drying process is designed in two stages. First, the rotating nozzle system blasts the components with hot, high purity compressed air and exposes them to hot air also filtered to a high degree.

The subsequent vacuum drying process uses vacuum to ensure that no water residue remains, even in recesses, narrow holes and areas that adre difficult to reach. “The vacuum process is, if you will, our additional insurance against moisture bloom, water stains or discoloration,” says Markus Lutter.

Authorized signatory Markus Lippoth also rates the investment in MAFAC cleaning technology and the cooperation with Thomas Gutmann's team as positive: “First test cleanings, followed by process optimizations through the MAFAC application engineers after commissioning have more than paid off.”

About Gebrüder Zepf Medizintechnik

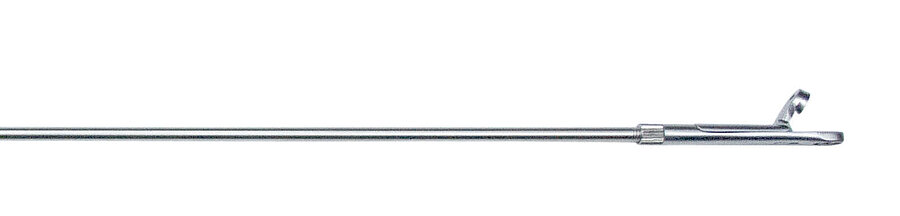

Founded in 1949 in Dürbheim near Tuttlingen, Germany's largest medical technology cluster, Gebrüder Zepf Medizintechnik GmbH & Co. KG has positioned itself as a premium supplier of surgical instruments for bone and spinal surgery. The main products in the portfolio today are bone punches in more than 8,000 variations and rongeurs, as well as medical forceps, curettes, and endoscopic sheaths. Thanks to the combination of traditional precision craftsmanship and state-of-the-art production methods, individual customer projects can also be realized in smaller quantities. The company, managed by Christoph and Tobias Zepf in the second and third generation, employs 65 people and supplies customers in Germany, Europe, the USA, Japan, and Australia.

Gebrüder Zepf Medizintechnik GmbH & Co. KG | 78589 Dürbheim | Germany