MAFAC rotating Ultrasonics: Cleanliness for the finest Structures – with patented Technology

Motion plus ultrasonics: Whether it is the finest, most complex workpieces or increased cleanliness requirements, ultrasonics are used as a complementary process to thoroughly remove particulate and filmic contamination. This works all the better with MAFAC rotating Ultrasonics.

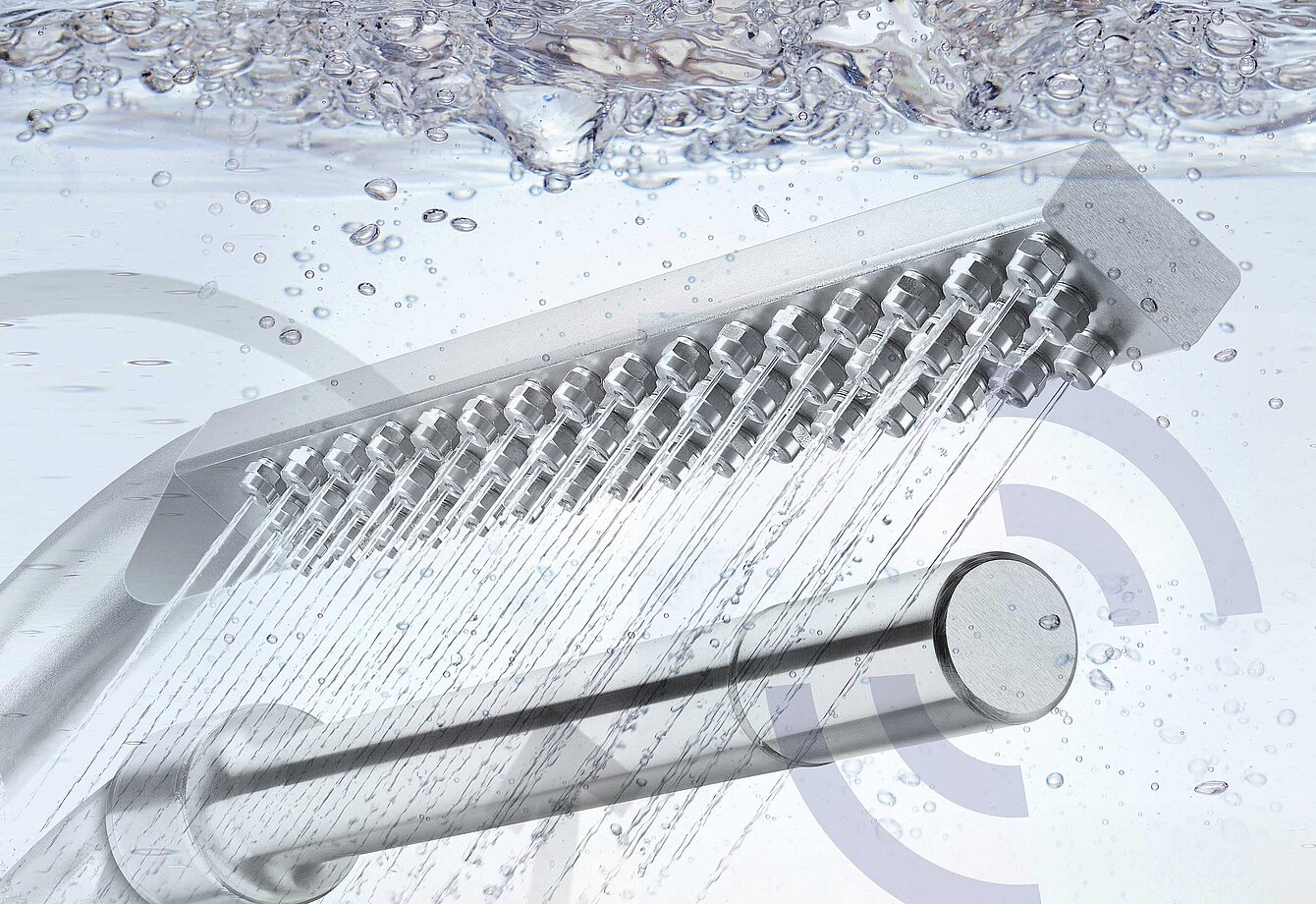

Our patented technology, integrated into chamber cleaning, increases the performance of the high-frequency sound waves through motion: the ultrasonic module moves with the basket. Acoustic energy reaches all surfaces evenly – without shadow zones typical of rigid systems. Critical geometries and heavy contamination can be targeted; delicate structures and sensitive materials are cleaned effectively and gently by reducing the acoustic input.

Complementary to our pressure-change technology MAFAC VAP, reproducibly high technical cleanliness is achieved. MAFAC rotating Ultrasonics is ideally suited for validated cleaning of instruments in medical technology, the removal of finest particles in optics and laser industries, or residue-free cleaning of complex geometries in semiconductor and additive manufacturing – even under cleanroom conditions.

Applications

MAFAC rotating ultrasound is suitable for applications involving sensitive surfaces and the highest technical cleanliness requirements. In medical technology, it enables the validated cleaning of instruments. In the optics and laser industry, it removes the finest particles from sensitive surfaces. In semiconductor manufacturing and additive manufacturing, the technology ensures residue-free cleaning of complex geometries – even under clean room conditions.

Technical Highlights for your Process

| • Uniform ultrasonic input: Rotation of the ultrasonic module enables sonication from all directions. |

| • Homogeneous energy distribution: Multidimensional sonication prevents shadow zones – even with complex components. |

| • ntensified cleaning effect: Cavitation generates local pressure impulses that reliably remove particulate and filmic contamination. |

| • Combination with MAFAC VAP: The technologies interact functionally during cleaning to achieve highly efficient results. |

| • Targeted energy input: Ultrasonic frequency can be adapted to the component, geometry and surface sensitivity. |

| • High process reliability: Precisely controllable ultrasonic power ensures reproducible results. |

Your Advantages with MAFAC rotating Ultrasonics

| • Patented MAFAC technology |

| • Excellent component cleanliness through cavitation plus rotation |

| • Uniform cleaning performance, even for complex components |

| • Targeted alignment to critical contours and areas |

| • Gentle cleaning of sensitive materials and structures |

| • Designed to meet the highest requirements for technical cleanliness |

The Operating Principle of MAFAC rotating Ultrasonics

In high-purity applications, components must be absolutely residue-free. Fine mechanical parts, electronic and optical components, or function-critical surfaces require industrial cleaning that reliably and reproducibly removes even the smallest particulate and film contamination. This is exactly where MAFAC rotating Ultrasonics makes the difference in the cleaning process.

Our patented, complementary technology is based on the principle of acoustic cavitation. High-frequency sound waves at 25 kHz and/or 40 kHz are transmitted into the cleaning medium. Microscopic vacuum bubbles form, expand, collapse and finally implode at high speed. These mini-implosions release mechanical energy that acts directly on the component surfaces and removes particulate and filmic contamination down to the micro level.

The key advantage over conventional ultrasonics: acoustic pulses are applied in motion – with rotation of the cleaning basket, spray jet and ultrasonic oscillators. Cavitation acts from changing directions, minimizing shadow zones and reliably reaching even complex structures. In combination with MAFAC VAP, rotating Ultrasonics ensures high cleanliness in validatable processes integrated into your sensitive manufacturing environments.

MAFAC rotating Ultrasonics FAQs

What distinguishes MAFAC rotating Ultrasonics?

MAFAC rotating Ultrasonics is a patented technology integrated into the chamber cleaning process. Unlike static ultrasonic systems, rotating ultrasonic transducers generate a homogeneous acoustic field. Shadow zones are minimized and the cleaning effect is intensified.

How does cavitation act in the cleaning process?

Ultrasonic waves generate microscopic vacuum bubbles in the cleaning medium. When these bubbles collapse, small local pressure impulses are released, mechanically removing contamination from component surfaces – without the use of chemical additives.

Is MAFAC rotating Ultrasonics suitable for highly sensitive components?

Yes. By selecting the appropriate frequency (25 kHz or 40 kHz), the process can be precisely adapted to the material, geometry and degree of contamination. This allows even sensitive surfaces and delicate structures to be cleaned safely and gently.

Can MAFAC rotating Ultrasonics be combined with other MAFAC cleaning technologies?

Yes. Especially in combination with the pressure-change technology MAFAC VAP, high technical cleanliness is achieved. The technologies complement each other functionally, enabling holistic cleaning with a high level of process reliability.