MAFAC ELBA: The versatile Parts Cleaning System

Robust technology, high flexibility, and solid cleaning performance: the MAFAC ELBA is consistently designed for continuous operation. In industrial parts cleaning, the system is used across a wide range of applications and reliably removes process residues, for example from mechanically machined workpieces.

Technical Highlights

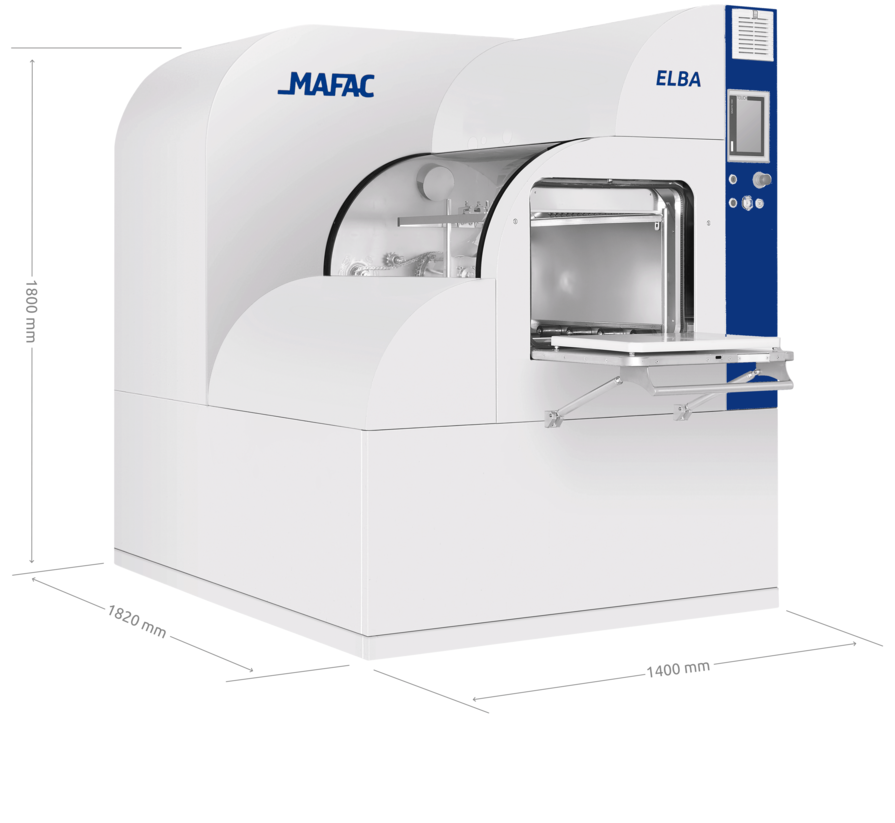

| • Compact dimensions: 1820 L x 1400 W x 1800 H mm |

| • Basket size: max. 660 L x 480 W x 338 H mm |

| • Process basis: Spray cleaning and rinsing with two-bath configuration for reliable cleanliness |

| • Batches: Max. weight 100 kg for cleaning even heavy workpieces |

| • Targeted drying: Pulse blowing or hot air for dry parts without residual moisture |

Applications

| • Metal processing: Cleaning of turned and milled parts as well as precision-manufactured workpieces |

| • Plastics processing: Cleaning of molded parts, injection-molded parts, and technical components |

| • Automotive industry: Cleaning of small parts and fastening elements |

For increased cleaning performance on a compact footprint

For increased cleaning performance on a compact footprint

Ideal for serial cleaning of parts with medium complexity

Ideal for serial cleaning of parts with medium complexity

For easy and convenient loading

For easy and convenient loading

Consistent performance even in continuous operation for maximum production reliability

Consistent performance even in continuous operation for maximum production reliability

Powerful cleaning for a wide range of industrial applications

Efficient and flexible: the two-bath parts cleaning system MAFAC ELBA is designed for continuous operation and suited for a wide range of industrial use cases with moderate requirement profiles. Whether for pre-cleaning, intermediate or final cleaning, workpieces with simple to complex geometries are cleaned and rinsed material-friendly and thoroughly. For targeted drying completely free of residual moisture, pulse-blowing or hot air are available.

The MAFAC ELBA is equipped with MAFAC Kinematics – our patented basic technology with rotation of the spray system and the cleaning load.

What sets the MAFAC ELBA apart:

| • Convincing cleaning quality for standard requirements |

| • High load capacity in a compact design |

| • Consistent performance even in continuous 24/7 operation |

| • Space-saving integration into existing production processes |

| • Efficient solution, particularly for metal processing |

MAFAC ELBA FAQs

Which typical parts are cleaned in the MAFAC ELBA?

In metal processing, the MAFAC ELBA is used, for example, to clean turned and milled parts, sheet metal, housings, and fastening elements. Whether bulk material, individual workpieces, or batches of identical parts, process residues from machining operations are reliably removed.

Is the MAFAC ELBA also suitable for cleaning heavy workpieces?

Yes. The MAFAC ELBA accommodates baskets with a maximum batch weight of up to 100 kg and therefore offers all the possibilities required for cleaning and drying large and heavy components as well.

Is the MAFAC ELBA a good choice for companies that require an uncomplicated cleaning solution?

Definitely. The MAFAC ELBA is robust and easy to operate and maintain, making it ideal for companies that value simple handling and durable technology. The process is always clearly visible, and loading is carried out at an ergonomic working height.