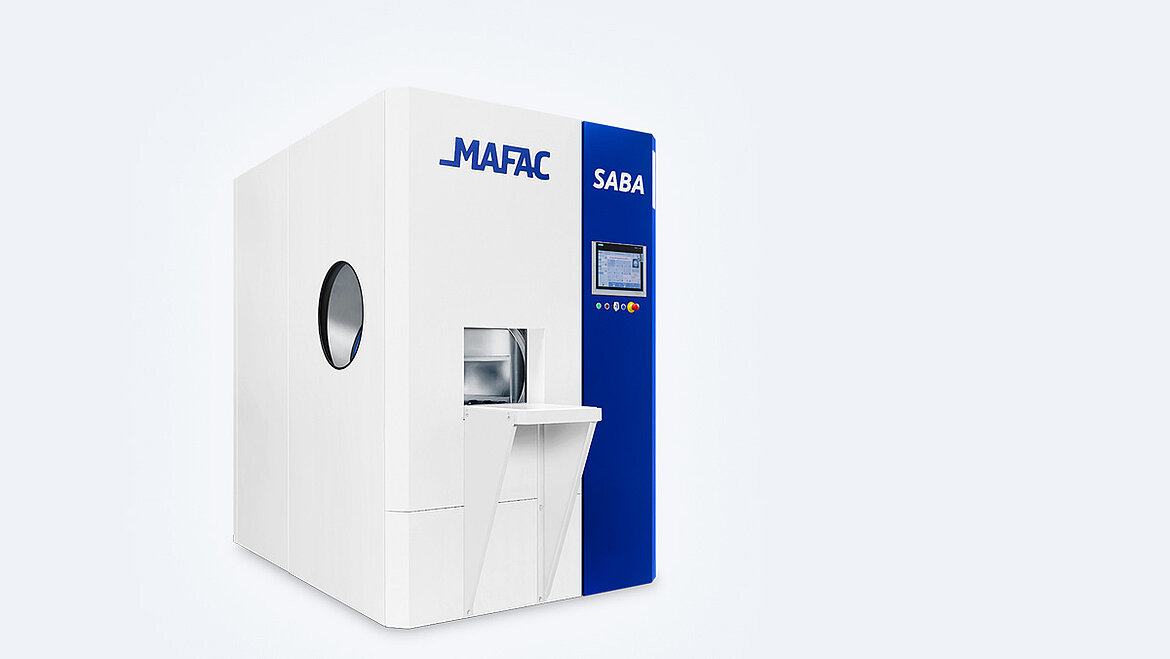

MAFAC SABA: The adaptive Concept Cleaning System

The MAFAC SABA is a compact spray-flood cleaning system designed as a modular entry point into high-purity cleaning. The standard version provides efficient cleaning and drying; retrofittable options such as the MAFAC VAP pressure change process, ultrasound, ultrapure water rinsing, and ultra-fine filtration allow the system to be gradually expanded into a fully-fledged high-purity process.

Technical Highlights

| • Compact dimensions: 2080 × 1450 × 2250 mm |

| • Basket dimensions: max. 520 × 320 × 300 mm – suitable for small to medium-sized components and prototype batches |

| • Process basis: Two-bath spray-flood concept as a solid basic platform for cleaning profiles |

| • Batches: max. batch weight 50 kg – efficient processing of small and medium batch sizes |

| • Retrofittable high-purity modules such as ultrasound with 25 and/or 40 kHz, rinsing with ultrapure water, ultra-fine filtration |

| • Versatile drying: hot air, pulse blowing, vacuum drying, infrared drying |

Applications

| • Laser technology/optics: cleaning of optical mounts, precision guides |

| • Medical technology: cleaning of cannulas, syringes, surgical tools |

| • Food industry: cleaning of filling valves, packaging, mixing components, cups, and trays |

| • Metal processing: Precision parts |

| • Additive manufacturing: Depowdering 3D prints |

Compact two-bath system, modularly expandable to meet increasing cleaning requirements

Compact two-bath system, modularly expandable to meet increasing cleaning requirements

Ensures reliable technical cleanliness up to high-purity applications

Ensures reliable technical cleanliness up to high-purity applications

Options MAFAC VAP and ultrasonics for superior, precisely controlled cleaning results

Options MAFAC VAP and ultrasonics for superior, precisely controlled cleaning results

Integrated and combinable drying methods such as hot air, pulse-blowing, vacuum, and infrared for targeted drying

Integrated and combinable drying methods such as hot air, pulse-blowing, vacuum, and infrared for targeted drying

Small Machine. Great Potential.

Looking for a compact, cost-effective parts cleaning system for solvent-free cleaning and visually spotless parts? A system that can be optimized later to meet increased requirements for new products and markets? Or, do you need to meet highest demands for particle and film cleanliness?

Grows with your needs

The clear answer to these questions is the new MAFAC SABA. The compact spray-flood system for smaller quantities is the intelligent evolution of our basic principle of a precisely matched configuration: As your tasks change, the MAFAC SABA grows with them thanks to its adaptive concept. Exactly when you need it.

Cleanlines made to measure:

With the basic version of the two-bath system and an individually designed cleaning process, you certainly achieve the desired level of cleanliness. Or we directly configure the MAFAC SABA for a demanding cleaning routine up to High Purity – for example for medical technology, laboratories or the food industry. MAFAC VAP, ultrasonics, infrared drying and an electropolished cleaning chamber are just some of the various options available.

Special features of the MAFAC SABA

| • Adaptive expansion concept |

| • High-purity options in a compact machine |

| • Low space requirements with high performance |

| • Standardized base, individual configuration |

An Eye to Future.

Armand Oostendorp, Managing Director MAFAC

MAFAC SABA FAQs

What are the differences between the MAFAC SABA and the other MAFAC cleaning systems?

The MAFAC SABA is a compact cleaning system for entry into high-purity cleaning. It offers a smaller basket size and is designed for small to medium-sized components. In addition, it can be expanded modularly—with options such as vacuum technology, ultrasound, ultrapure water rinsing, etc.

For which part sizes and quantities is the SABA suitable?

With a basket size of 520 × 320 × 300 mm, the SABA is ideal for small and medium-sized parts. It works particularly efficiently with medium quantities, as is common in laser technology, medical technology, and optics. MAFAC offers suitable machines for large or heavy components in its portfolio.

Is MAFAC SABA a flexible cleaning system?

The MAFAC SABA can be quickly adjusted to different components and materials—from metal parts to plastics, glass, silicone, and even highly sensitive workpieces with complex geometries. The cleaning programs can be customized individually, ensuring that the system delivers reliable results even when requirements change.

Can the MAFAC SABA be retrofitted or upgraded at a later date?

Yes. The adaptive machine concept allows for the retrofitting of high-purity technologies such as vacuum technology (VAP), ultrapure water rinsing, ultra-fine filtration, and ultrasound. This means that the SABA grows with your requirements—from simple degreasing to high-purity fine cleaning in medical technology, the food industry, laser technology, or optics.