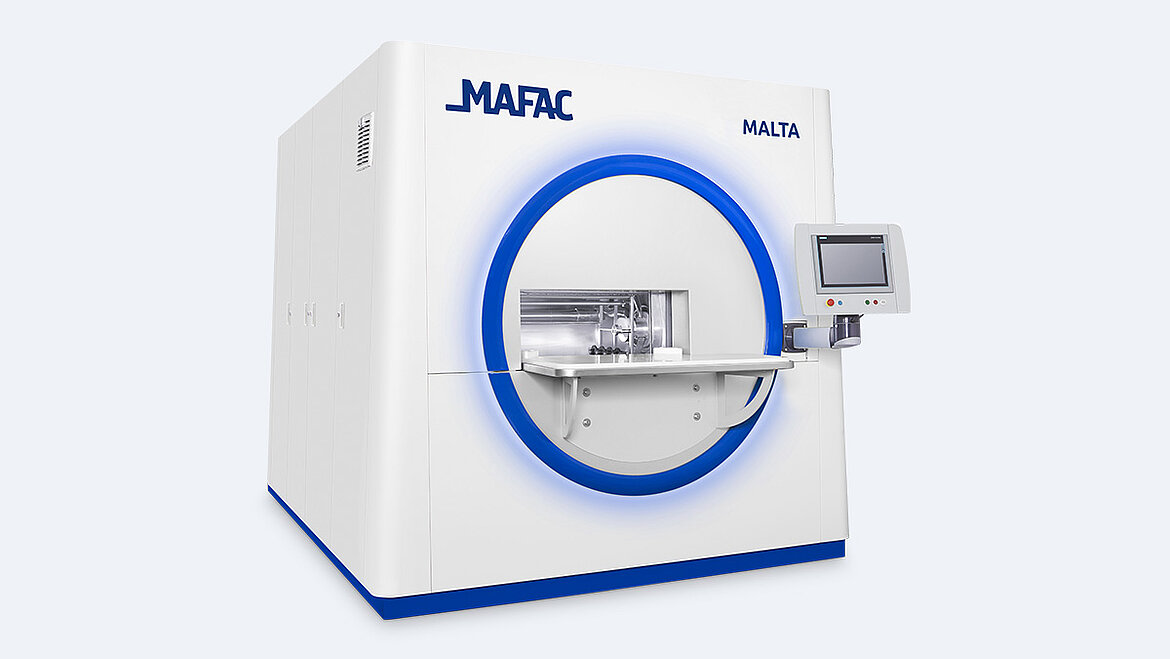

MAFAC MALTA: The Cleaning System for sensitive Applications

Developed for the highest requirements in component cleanliness, the compact MAFAC MALTA delivers reproducible high-purity results – even for complex geometries and demanding industry standards, including medical technology, laser industry, additive manufacturing, semiconductor and food industries. Powerful MAFAC technologies combined with targeted drying ensure efficient and stable cleaning processes.

Technical Highlights

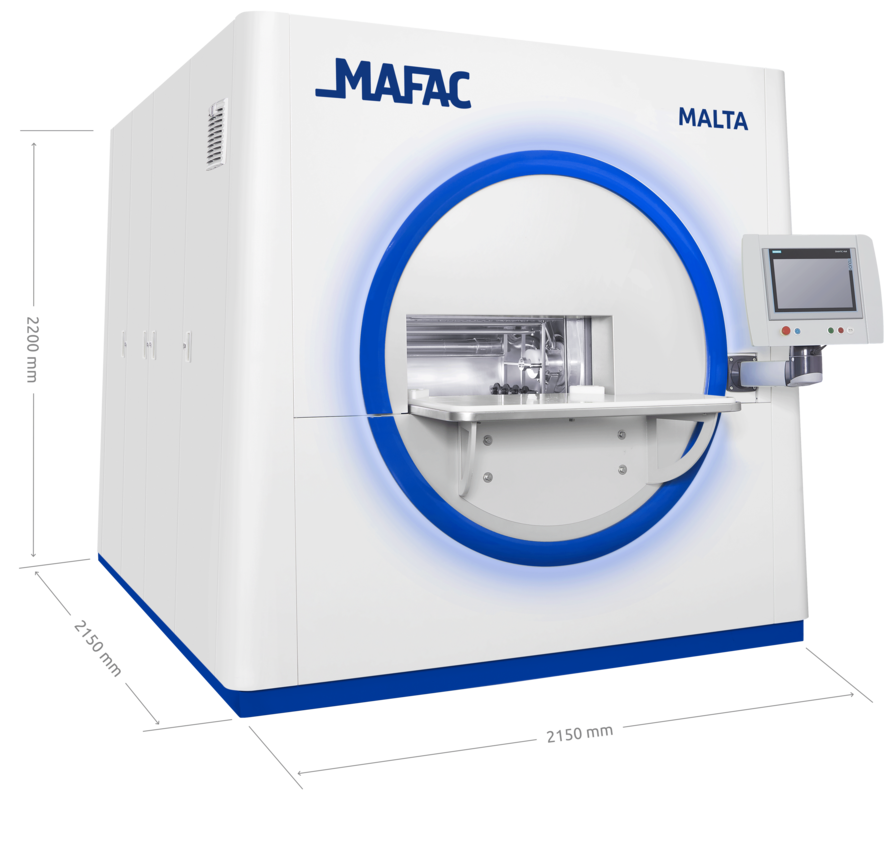

| • Compact dimensions: 2150 L × 2150 W × 2200 H mm |

| • Basket size: max. 521 L × 321 W × 200 H mm for small to medium production runs of components and prototypes |

| • Process basis: Spray-flood cleaning concept with three-bath configuration for superior cleanliness |

| • Batches: max. weight 75 kg for efficient cleaning of small to medium lot sizes |

| • Upgrade option: High-purity modules including ultrasonics (25/40 kHz), ultrapure water rinsing, and ultrafine filtration |

| • Versatile drying: hot air, pulse blowing, vacuum drying, infrared |

Applications

| • Optics: Cleaning of optical mounts, precision guides, and measurement optics components |

| • Medical technology: Cleaning of cannulas, surgical instruments, and syringe components |

| • Food industry: Cleaning of filling valves, packaging trays, mixing tools, cups, and trays |

| • Semiconductor industry: Cleaning of housings, holders, and precision-manufactured components |

| • Additive manufacturing / 3D printing: Cleaning of components, removal of powder residues and support structure remnants |

| • Precision engineering: Cleaning of fine-mechanical components, instrument parts, and micro-mechanics |

| • Plastics processing: Cleaning of parts after demolding, assembly components, and housing elements |

Meeting the highest cleanliness standards, e.g. in medical technology, laser, and semiconductor industries

Meeting the highest cleanliness standards, e.g. in medical technology, laser, and semiconductor industries

Perfect addition for consistently top-level cleanliness up to final packaging

Perfect addition for consistently top-level cleanliness up to final packaging

As high-end as necessary – matched to specific purity requirements

As high-end as necessary – matched to specific purity requirements

Delivers superior technical cleanliness on a compact footprint

Delivers superior technical cleanliness on a compact footprint

For uncompromising cleanliness with cleaning, rinsing, and final rinsing

For uncompromising cleanliness with cleaning, rinsing, and final rinsing

Pure cleanliness for demanding industries

Optics, electrical engineering, laser industry, medical technology, pharmaceutical and food industries: Wherever the highest requirements and industry standards must be met reliably and repeatedly, the compact MAFAC MALTA is the right solution. A system infrastructure consistently designed for cleanliness and patented technologies ensure excellent cleanliness, both filmic and particulate.

The MAFAC MALTA can be customized with the following technologies: MAFAC Vectorkinematics, MAFAC VAP (Pressure Change Technology) and MAFAC rotating Ultrasonics.

What sets the MAFAC MALTA apart:

| • Designed for the highest cleanliness requirements |

| • Compact process solution with a focus on high purity |

| • Targeted cleaning and drying of complex geometries |

| • Process solutions based on coordinated MAFAC technologies |

MAFAC MALTA FAQs

For which industries is the MAFAC MALTA particularly suitable?

Primarily for medical technology, the laser industry, various areas of food production, additive manufacturing (3D printing), and semiconductor manufacturing — in short, wherever uncompromising cleanliness is required.

Can the MAFAC MALTA also reliably clean fine bores or internal channels?

Yes. The combined rotation of the basket and nozzle arm ensures that even complex geometries are uniformly reached by the cleaning medium. This makes it possible to thoroughly clean the smallest bores and internal channels.

The use of the MAFAC VAP technology further enhances this effect: vacuum and pressure changes enable intensive flow through hard-to-reach internal areas, ensuring reliable removal of residues. The result is a reproducibly high cleaning quality, even for highly demanding component geometries.

Does the MAFAC MALTA offer powerful drying?

Yes, absolutely. Powerful drying in combination with targeted basket movement ensures that moisture is reliably removed even from undercuts, channels, and bores. Excellent drying results are also achieved with materials that have a low tendency to dry, such as plastics.

How reliably does the MAFAC MALTA remove powder residues from additively manufactured components?

Especially for additively manufactured components, the combination of spray-flood cleaning and MAFAC VAP is particularly effective. Powder residues, support structures, and loose particles are removed reliably and reproducibly, preparing the components optimally for further processing.