MAFAC JAVA: The Cleaning System for complex Geometries

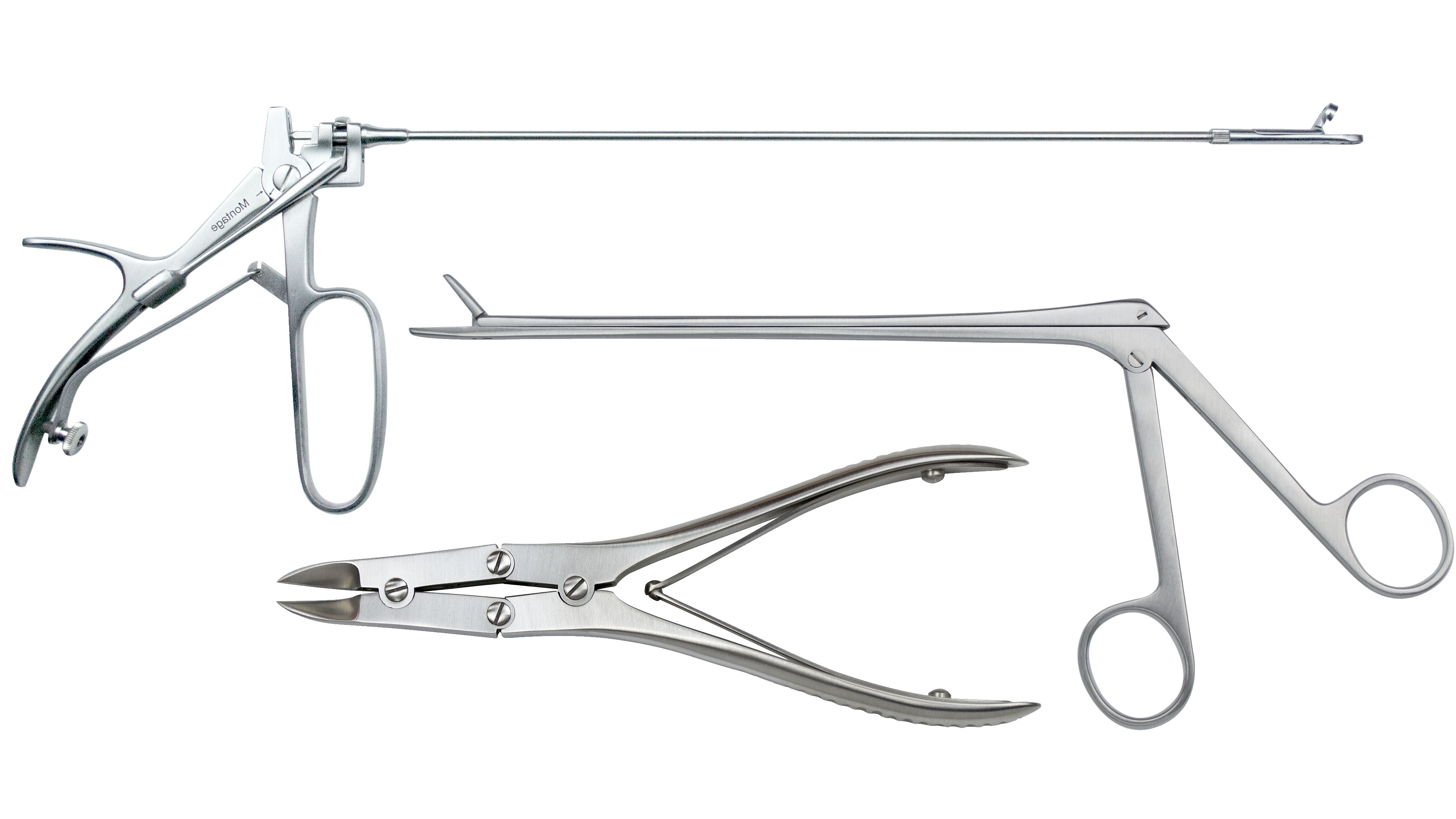

Reproducible cleanliness for complex geometries and critical processes

Demanding geometries, sensitive process chains such as medical technology, or both: spray and flood cleaning plus optional MAFAC VAP and rotating ultrasound ensure reproducible, optimized pre-cleaning and final cleaning, even in hard-to-reach areas. For perfectly dry parts, impulse blowing, hot air and vacuum drying can be combined.

MAFAC JAVA can be customized with this Technology:

CLEANING STORIES – MAFAC JAVA real-World Application

Your Products and Specifications. Your Cleaning System.

Together with you, we design “your” MAFAC, your process. With everything that goes with it. As standardized as possible, as individual as necessary. For precise cleaning and drying, right from the start and in the long term. Talk to us about the right solution for your cleaning challenge! We will provide you with non-binding, targeted advice – based on the information you supply in the inquiry form.