MAFAC is a partner of ETA-Factory

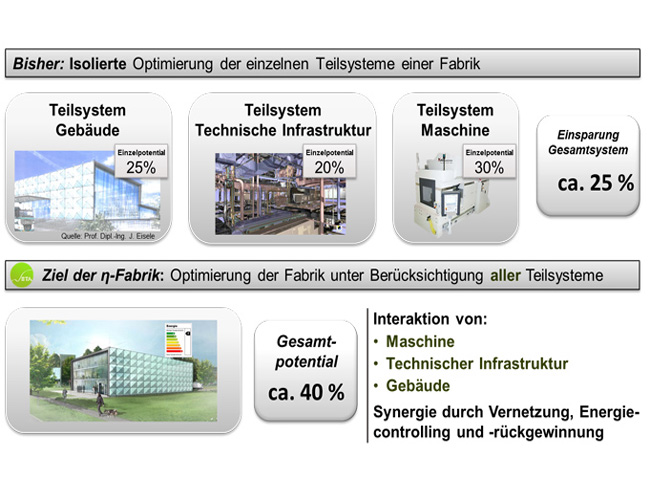

In its project "Energy-efficient factory", the Institut für Produktionsmanagement, Technologie und Werkzeugmaschinen (PTW) of Darmstadt Technical University investigates the energy savings potential in industrial production by co-action of all company departments.

The "Energieeffizienten Fabrik für interdisziplinäre Technologie- und Anwendungsforschung" (ETA) is the first tool to investigate and optimize the energy efficiency of the entire industrial production process.

For this purpose, a representative process chain with high optimization potential was selected. In addition to three metal-cutting processes and one thermal treatment process, two cleaning processes - implemented by MAFAC - are part of the picture. Among others, BMW, BOSCH, DAIMLER, EMAG, BOSCH Rexroth, OPEL, SIEMENS, Stuttgart university, and VIESSMANN are also involved in the research team.