Technique

MAFAC Vacuum Activated Purification

New process for capillary component geometries

Components with narrow capillary structures and angled ducts are a great challenge in parts cleaning – especially if high demands on cleanliness have to be met at increasing costs. With the new MAFAC Vacuum Activated Purification (VAP), MAFAC offers a process for these applications which reliably and economically cleans even deep drilled holes with narrow cross sections on an aqueous basis.

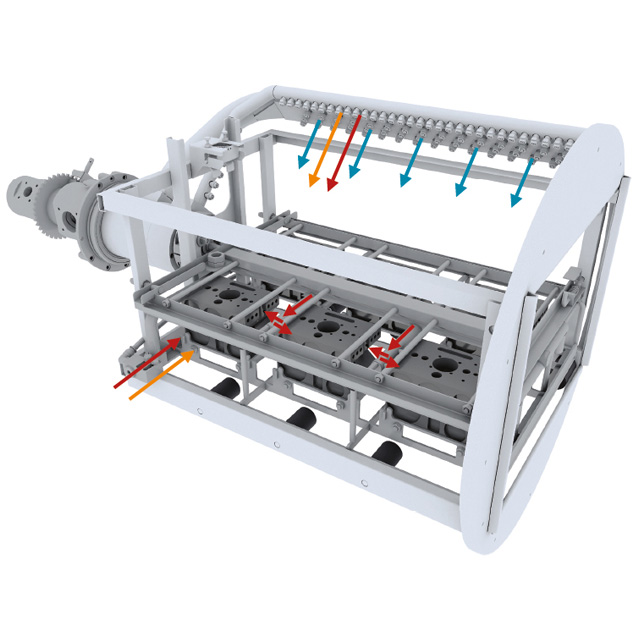

MAFAC Vector Kinematics

Higher faster further!

A new dimension of dynamic cleaning - 60 % higher application on the component surfaces.

Targeted cleaning and drying

Targeted cleaning and drying

Every day, manufacturers of parts with a complex design face the challenge of how to clean difficult-to-access parts such as undercuts, blind bores, or intricate channels efficiently and reliably.