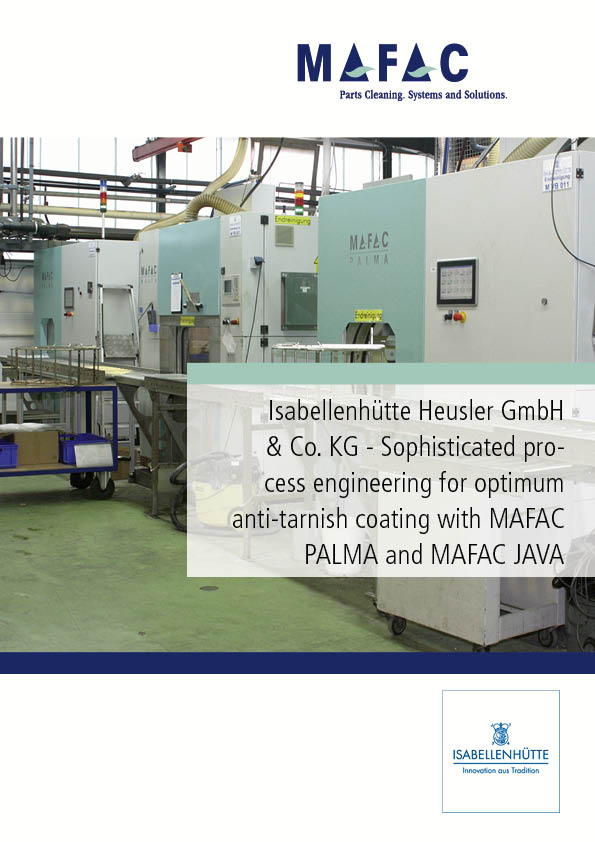

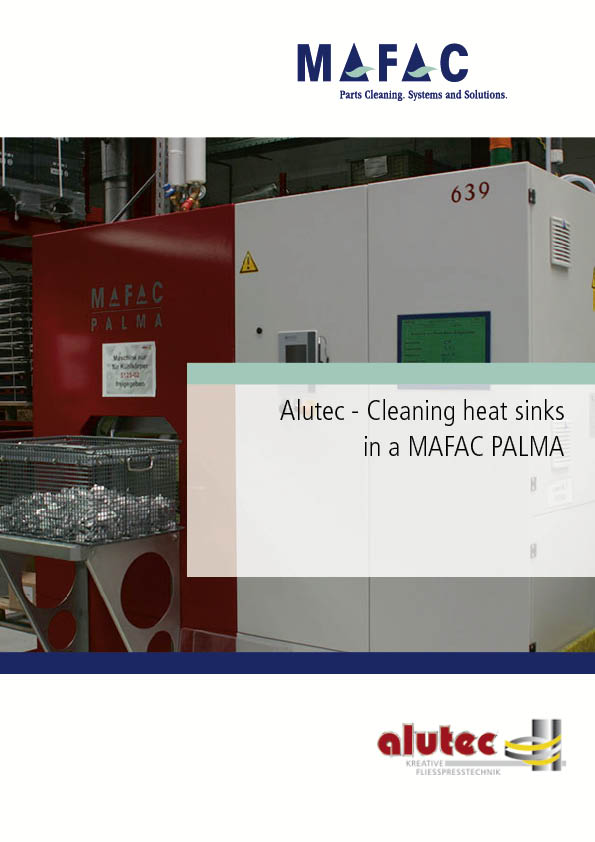

MAFAC PALMA - Spray and flood cleaning perfectly combined

The MAFAC PALMA offers ideal features for process-safe cleaning of sensitive parts with complex shapes. During the wet phase, spray and flood cleaning can be individually combined to achieve optimal cleaning results. A special quick-flood system allows for full flooding of the cleaning chamber within only 30 seconds.

Optional: Ultrasonic unit for ultrafine cleaning

For applications with very high demands on cleanliness, e.g. in the watch-making industry, in medical technology and precision engineering, the system can be equipped with an optional ultrasonic unit. The exact fine adjustment of the performance design of the ultrasonic processes ensures a perfect alignment with customer-specific requirements. If needed, the MAFAC PALMA can be equipped with a third holding tank to integrate an additional wet process.

For applications with very high demands on cleanliness, e.g. in the watch-making industry, in medical technology and precision engineering, the system can be equipped with an optional ultrasonic unit. The exact fine adjustment of the performance design of the ultrasonic processes ensures a perfect alignment with customer-specific requirements. If needed, the MAFAC PALMA can be equipped with a third holding tank to integrate an additional wet process.

Energy-efficient: Rotating hot air drying system

Based on the patented basketspray frame rotation, MAFAC has developed a special hot air flow drying system. It is especially designed for high-quality full body drying of parts with complex shapes, in particular for parts with recessed areas, e.g. narrow bevels and undercuts. As a result, process times are reduced while efficiency is increased significantly due to the enhanced drying performance.

Based on the patented basketspray frame rotation, MAFAC has developed a special hot air flow drying system. It is especially designed for high-quality full body drying of parts with complex shapes, in particular for parts with recessed areas, e.g. narrow bevels and undercuts. As a result, process times are reduced while efficiency is increased significantly due to the enhanced drying performance.

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Standard features and options

Standard features:

- Patented rotating, multi-sided spray system with counter-rotating basket receptacle system. A special nozzle arrangement ensures reliable cleaning results

- Front loading with vertical sliding door and loading table

- Spray cleaning, flood cleaning and rinsing in one machine

- Large holding tanks with cascaded design for a long useful bath life

- Standard Euro baskets can be used (600L X 400B 288H mm)

- Removable basket filter for collecting coarse dirt particles in the return flow from the cleaning/rinsing process

- Separate bath heating system with digital temperature control and limitation

- Steam extraction with condensation and mist separator

- Powerful coalescing oil separator with maximum monitoring of the oil collection tank

- Automatic medium level control

- Thermal insulation of the holding tank

- Water contact components made of stainless steel / plastic

- Easy-to-use MAFAC MAVIATIC touch panel

- Floodable cleaning chamber

Options:

- Rotating hot air impulse blowing system

- Combined rotating hot air impulse blowing and hot air drying system

- Vacuum drying

- Additional spray process with holding tank 3

- Ultrasonic cleaning system incl. parabolic reflector for optimum efficiency of the ultrasonic waves

- Window in the cleaning chamber allows observation of the cleaning process

- Working tank adaptation to 660L x 480W x 338H mm

- Mechanical main stream ultrafine filtration with filter bags or filter candles

- Speed control for basket rotation including rocking motion

- Speed control of nozzle rotation

- Program package for machine pre-heating and media treatment

- Complete demineralising unit

- Automatic chemicals dosing

- Draining pump

- Collecting tray in accordance with Cl. 19 German Water Management Act (WHG) including oil level sensor

- Charging trolley

- Manual roller conveyor

- Automatic transfer system

- Modem for remote maintenance of the control system

- User-friendly MAFAC MAVIATIC touch panel,12 inch, with graphic process visualisation

- Frequency-controlled pump pressure

- Reinforced pump systems

- Rinse water treatment module

- Fresh water rinsing system

- Heat exchange module MAFAC HEAT.X

- Targeted cleaning and drying

- Vector kinematics

- Customised colours

- Larger versions and further options on request

More information

For detailed technical information please refer to our product overview.