MAFAC Vector Kinematics

Higher

- Higher quality through higher impact - 60 % better than with rigid nozzle systems

Faster

- Achieving the same result in a shorter time!

Further

- More than one step ahead - with MAFAC vector kinematics you are well prepared for the future.

You can find more details here.

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

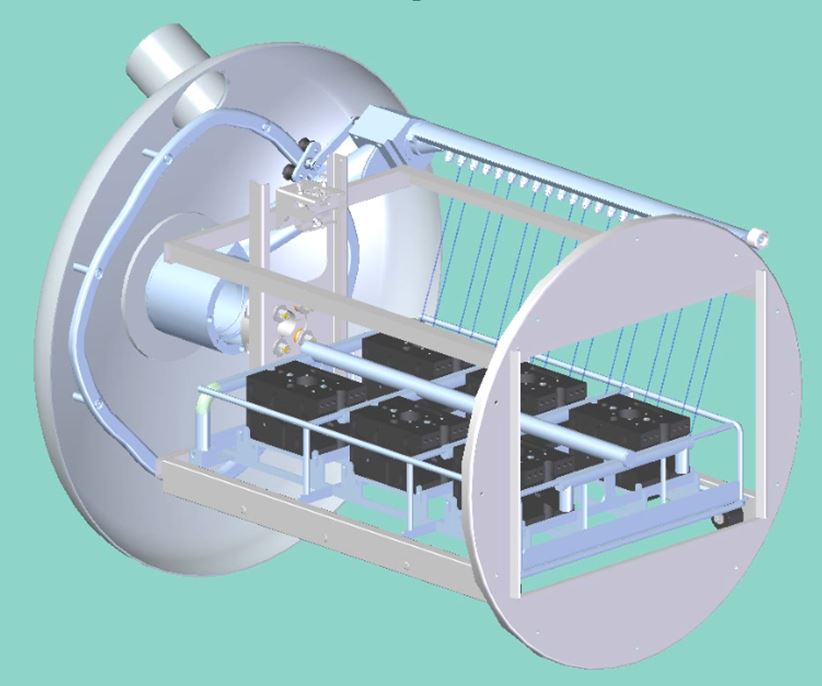

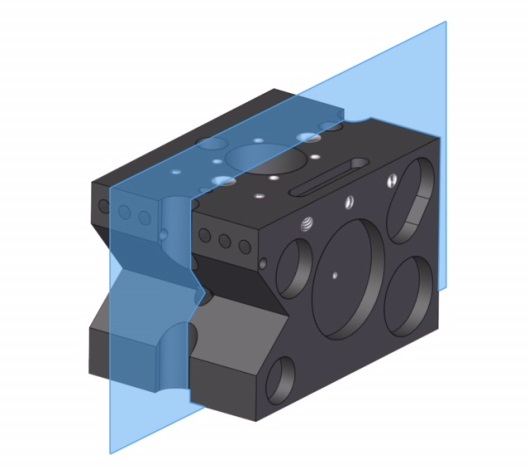

Workpieces with complex geometries such as drilled holes and undercuts, in particular, benefit from the targeted turbulences of MAFAC vector kinematics.

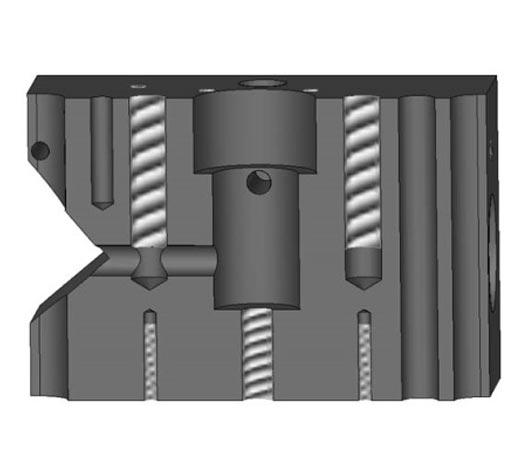

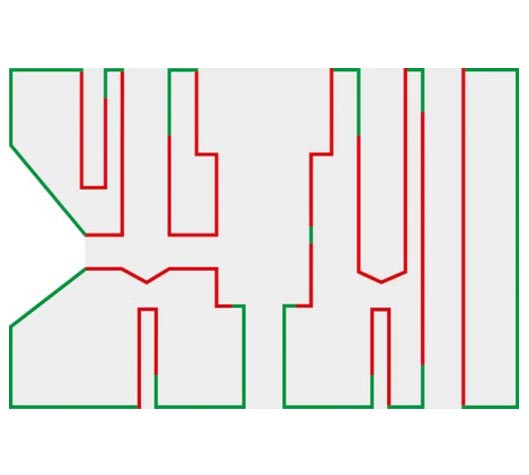

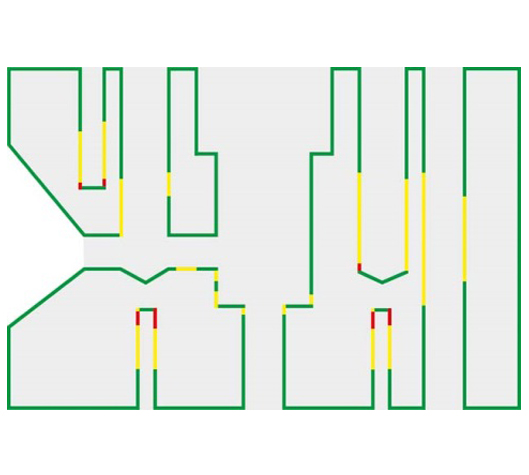

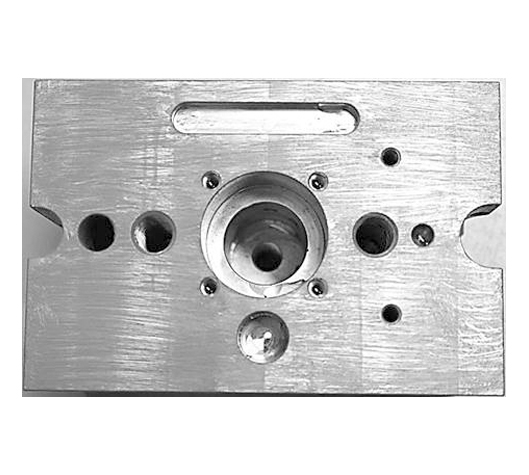

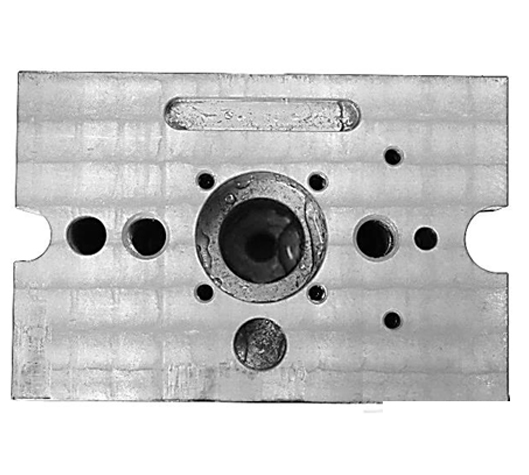

Sectional view of the MAFAC normative part.

In cleaning processes with a rigid nozzle system, the partial regions which are not exposed (red) outweigh those which are optimally exposed (green).

Thanks to angular variance, the MAFAC vector kinematics leads to a significantly better exposure of the components. Optimally (green) and partially (yellow) exposed regions clearly outweigh unreached locations (red).

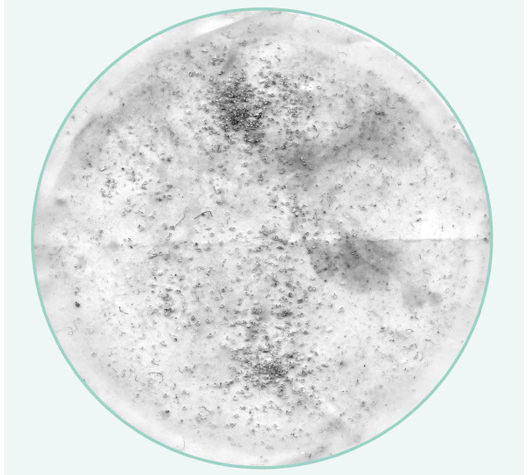

Residual dirt of a component that was treated with a cleaning method using a rigid nozzle system.

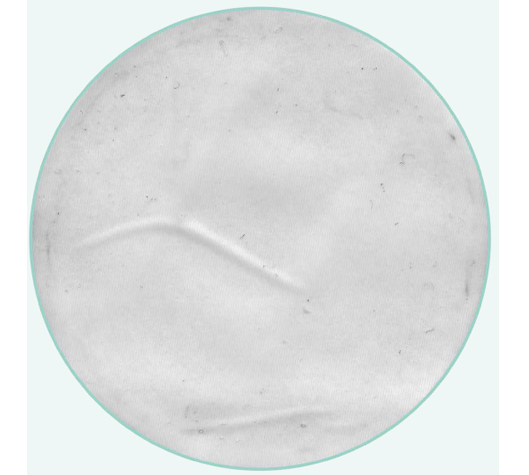

Almost free from particles: The surface of a component cleaned with MAFAC vector kinematics: The weight of particulate contamination is 30 % lower than with a stationary spray tube.

Rigid nozzle system

Uncleaned surface area: 1,009,926 mm²

Cleaned surface area: 142,980 mm²

MAFAC vector kinematics

Uncleaned surface area: 1,009,926 mm²

Cleaned surface area: 426,928 mm²

More information

User reports and technical information

YouTube videos

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren