Targeted cleaning and drying

Every day, manufacturers of parts with a complex design face the challenge of how to clean difficult-to-access parts such as undercuts, blind bores, or intricate channels efficiently and reliably. In most cases, valuable resources and much time are invested with the result that the easy-to-access parts are “overcleaned” before the cleanliness of the hidden interior contours meets the strict specifications.

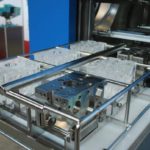

For these requirements, MAFAC developed a new process for targeted cleaning, rinsing and drying of certain sections of the part, addressing in particular manufacturers in the hydraulics and diecasting industry.

Functionality

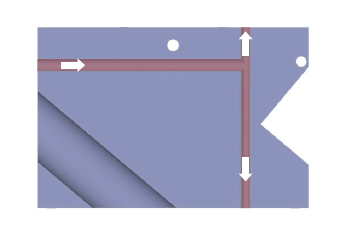

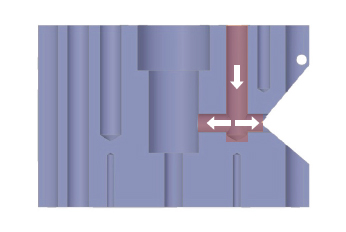

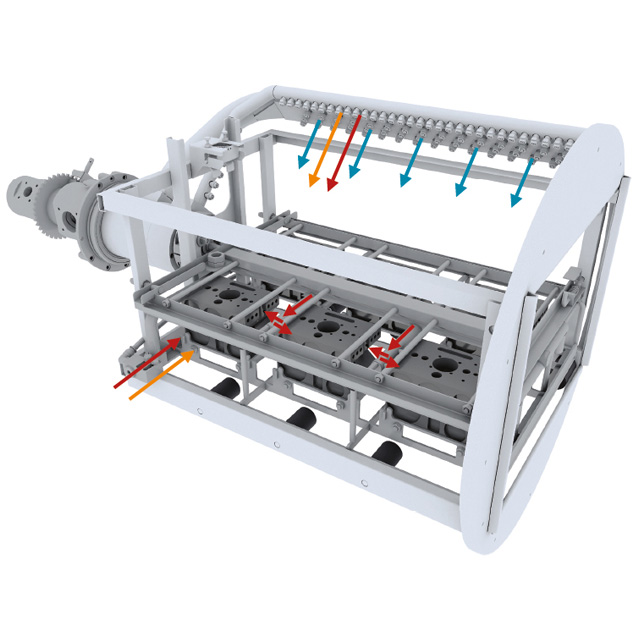

The heart of the new process for targeted cleaning and drying is the tool positioning system (TPS) adjusted individually to the parts to be cleaned. The parts are locked into position in the TPS. Via integrated nozzles tailored to the part, water or air are guided directly to the bores, channels or holes to be cleaned.

The newly developed central bearing kinematics with dual-channel rotary feedthrough aim the cleaning medium directly at difficult-toreach interior geometries, making it flow through them with a high degree of turbulence.

Benefits

- Directly aimed flow of the cleaning medium through interior geometries

- Combination with global cleaning and drying in rotation process

- Lower process temperatures

- Energy and resources are saved, which makes the process efficient

- Reduced consumption of cleaning chemicals

- Shorter process times

- Added flexibility: With several TPSs, one machine can clean and dry parts of highly different shapes

- Reproducible quality

More information

Technical information

YouTube videos

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren