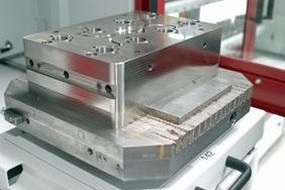

Toolmaking applications

We have already been able to convince many well-known customers in the toolmaking industry with our compact series machines, which can be optimally integrated into an automated production step. Our ideal goal is to integrate the cleaning machine

into a complete production line and to provide for a flexible and demand-oriented supply and discharge of the items to be cleaned. Depending on the requirements, the tool is milled, die-sunk or machined using alternative methods in the processing unit, then transported to the cleaning system by means of a robot. After the cleaning process, the parts are correspondingly clean and dry and have the optimum temperature for a subsequent measuring process. In the consulting process, we carry out an in-depth analysis of the task at hand and provide you with a suitable solution for every detail.

Range of parts

eroded tools or parts after machining, fixed on EROWA clamping systems

stamping tools

Contaminations

erosion sludge

chips

oils

Materials

steel

stainless steel

aluminium

copper

User reports