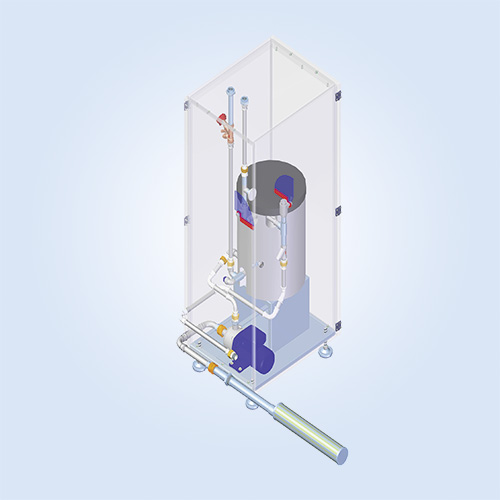

MAFAC HEAT.X

Heat exchange module for hot water

The heat exchange module MAFAC HEAT.X provides an alternative to electrical heating of cleaning agents: the utilization of the available external heat. The module works with a highly efficient heat exchange process. The available heating agent flows through a coaxial heat exchanger, while the cleaning agent which needs to be heated is fed to the same heat exchanger but runs through a separate pipe. In counterflow principle, the heating agent warms up the cleaning agent by means of direct heat transmission. The cleaning agent is then returned to the cleaning process.

In this way, electricity for heating may be replaced by alternative energy sources:

- use of waste/industrial water following heat treatment (e.g. in foundries)

- from cogeneration

- regenerative water heating applications (solar heat)

The heat exchange module can also be operated in mixed operation with electricity and water and can be connected to a wide range of machines, not only to MAFAC parts washers. Whether you are preparing for the purchase of a new machine or the execution of a major project, our project planning department will be glad to develop an individual solution.

How will you benefit from using a heat exchange module?

- Potential reduction of the power consumption for bath heating of max. 60%

- Electricity tax refund if you implement energy management systems (DIN EN ISO 50001) and/or environmental management systems (DIN EN ISO 14001)

- Reduction of CO2 emissions (617 g CO2/kWhEnd according to GEMIS power mix Germany).

- Potential reduction of the connected load of the machine of up to 50% (if heated only with water)

- Fast availability of technical heat thanks to the highly integrated power density in the heat exchanger

- No waste of existing heat because sources of warm production water are used

Technical details

Standard equipment:

General:

- Heat exchange system in coaxial pipe technology

- Robust, self-cleaning, low-maintenance heat exchange process

- Sheet steel housing painted in RAL 7035

- High-quality insulation of all fluid-carrying components

Machine-side:

- Circular pump for process water

- One-way restrictor

- Suction filtration 1,000 µm

- Ventilation connection

Heat supply side:

- Analog temperature display for hot water

- Regulating stop valve

- Manual stop ball valve

- Drain connection / system draining

Options:

- The energy monitoring feature gives you a constant overview of the consumption.

- Retrofit kits are available to connect the heat exchange system to your machines.

- Chemical rinsing units for removal of contamination films in the pipe system and in the heat exchanger.

- Additional filtration unit for extension of the useful life of the complete volume of agents required for the cleaning process.

- Mixed process operation possible (electrical and water heating).