Kinematics meet ultrasonic – MAFAC obtains a patent for the ultrasonic technology of the MAFAC MALTA

MAFAC, the manufacturer of machines for aqueous parts cleaning, is the first to combine the principles of kinematics with ultrasonic technology: the MAFAC MALTA is equipped with a rotating and movable ultrasonic unit. Patent protection for this technology was recently obtained, increasing the number of patents MAFAC holds in the field of kinematics.

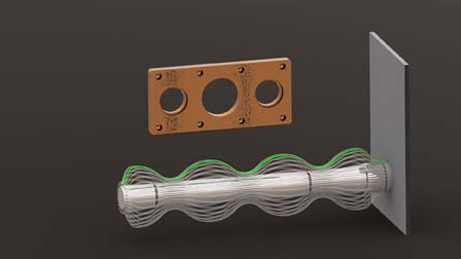

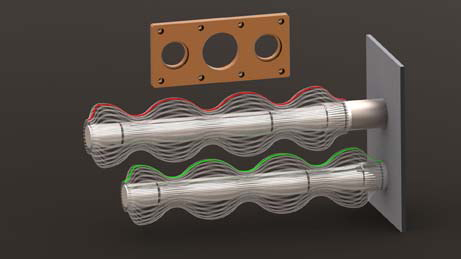

The smaller and more complex the parts, the more difficult they are to clean. To ensure that aqueous processes will achieve premium results also for novel parts and thus meet the customers' increasing requirements, MAFAC developed a new process in ultrasonic cleaning, converting the method of basket-and-nozzle rotation to ultrasonic technology. To this end, the ultrasonic oscillator rotates as well; circling around the basket receptacle system, it achieves an even better distribution of the sonic waves inside the chamber. The ultrasound hits the parts from all sides, significantly reducing the shadow zones. The possibility to target the ultrasound directly at difficult-to-access surfaces allows for intensive sonication.

Thanks to a multitude of new technological features, the MAFAC MALTA allows for premium-quality, efficient parts cleaning. It is equipped with patented ultrasonic technology and rotating ultrasonic oscillators. The resulting turbulences increase the cleaning effect.

Coordinated functions for optimum sonication

In addition to the rotation function of the ultrasonic oscillators, the MAFAC MALTA has other coordinated features which provide for particularly efficient ultrasonic cleaning:

1. Optimum arrangement of the ultrasonic oscillators for added efficiency

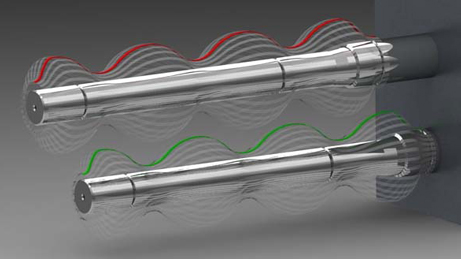

The ultrasonic oscillators of the MAFAC MALTA are arranged offset by a quarter wavelength (1/4 λ). Thanks to this effect, peaks and troughs of a wave alternate smoothly, and full sonic power can be applied to the parts.

2. Direct targeting of the angle positions for added precision

The MAFAC MALTA allows the user to control the position of the parts and target the correlative sonic source directly by means of accurate control commands, for example for angle position. In this way, the machine can directly move to critical part geometries and heavily contaminated surfaces and treated in a targeted manner. Furthermore, the operator can use angle measurement in the cleaning program to specify which spots in a component should be treated more intensively with ultrasonic. Analogously, it is also possible to reduce the sonication in certain spots for effective but gentle and energy-efficient cleaning of intricate structures.

3. More frequencies for added flexibility

Depending on the degree of contamination and on the surface, the MAFAC MALTA offers two different frequencies: Choose between 25 kHz for higher requirements or coarser contamination, and 40 kHz for sensitive parts. Furthermore, the infinitely variable control of the ultrasound additionally allows for process-specific, adaptable dosing of the sound power. This saves energy and resources and keeps resonator wear to a minimum. The design also makes it possible to combine ultrasonic cleaning with treatment via a rotating kinematic process at 25 and 40 kHz.

In conclusion, MAFAC's new ultrasonic technology is designed for high flexibility and efficiency. It offers a large number of variation options in terms of sound frequency, intensity, and duration, and – as a new feature – also in terms of movement and positioning in space. Thus, parts cleaning is tailored to the customer's individual requirements. This has made the entire process more efficient and ensures that premium results are achieved reliably, with a shorter cleaning time and reduced energy consumption.

On Telsonic AG Bronschhofen/Switzerland

As an internationally operating company in the area of industrial ultrasonic technology, Telsonic AG is one of the global market leaders.

Established in 1966, the company headquartered in Bronschhofen/Switzerland has a staff of 200 employees all over the world.

It has affiliates in the UK, Germany, the USA; Serbia, and China, as well as agencies in many other countries.

Based on their many years of experience and continuous further technological development, Telsonic offers state-of-the-art ultrasonic generators, oscillator systems, and system solutions meeting a wide range of customer requirements. Our experiences sales engineers and application specialist identify the optimum system concept for your individual application, based on precisely defined specifications.

During the entire sales process, the customers are supported and advised by our competent team. Our highly qualified and experienced service team helps to ensure a long service life of the ultrasonic units and systems and always has a competent answer to any questions you may have.

If necessary, the ultrasound unit of the MAFAC MALTA can be rotated and moved to target critical parts geometries directly.

The ultrasonic oscillators of the MAFAC MALTA are offset for greater effect of the ultrasonic treatment. Different sound frequencies increase the flexibility.

With ultrasonic oscillators installed in cleaning chambers, the cleaning results will not always be perfect if they are not exposed to the sound long enough.

back to last page

back to overview