Getting energy costs under control – Full thermal insulation offers high savings potential in aqueous parts cleaning

Alpirsbach, in October 2016 – Aqueous parts cleaning is a value-adding but also energy-intensive step of the manufacturing process. In the course of the ongoing discussion on ecological manufacturing, the machine manufacturer MAFAC recently proved that merely by providing full thermal insulation for their cleaning machine, production companies could significantly reduce their energy consumption. This was evidenced by scientific tests in the frame of the ETA research project of Darmstadt Technical University.

The research results were based on the systematic investigation of a spray-flood cleaning machine of the the MAFAC JAVA with full thermal insulation, using a standardized cleaning and drying process. The result: Full thermal insulation can significantly reduce the energy consumption of a cleaning machine. But this is not all: Additionally, the working conditions in the vicinity of the machine as well as its effects on the environment are improved.

Savings potential due to full thermal insulation

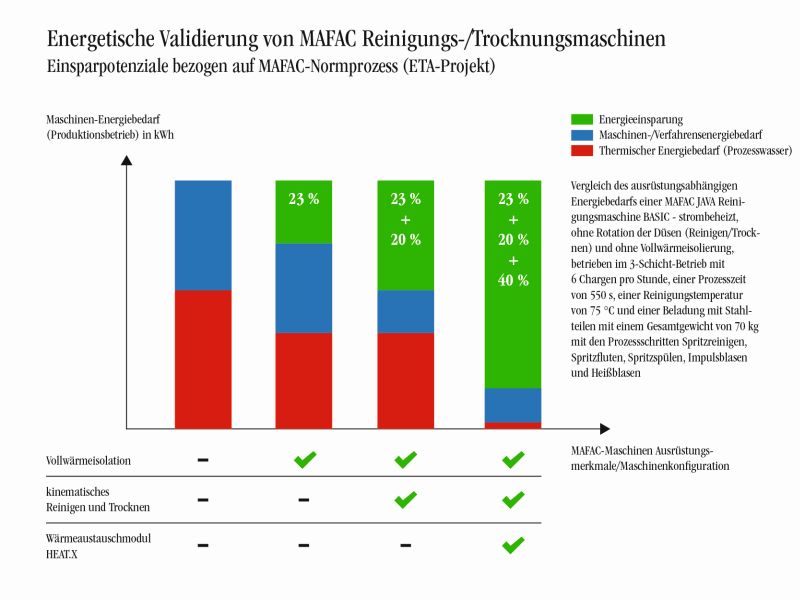

More than 950 test measurements with a defined standardized batch for four different temperature clusters (48 °C, 57 °C, 66 °C, 75 °C) and five different machine modes confirm the energy savings potential. The machine ran for 21 hours per day in three-shift operation, and the result was scaled to 48 production weeks. Compared to a MAFAC JAVA without thermal insulation, the calculated results showed an energy advantage of 23 per cent and a reduction of the CO2 emission per annum of approximately 46 tons.

Other benefits of full thermal insulation

In addition to the directly resulting reduction of energy consumption and carbon dioxide emissions, full thermal insulation has other benefits which, beyond the limits of the machine itself, help to improve the working conditions on site, the building management, the load on the environment, and the total costs. For instance, thermal insulation provably reduces the heat emissions of the machine surface by 40 per cent. The temperature in the proximity of the machine and thus the working climate are more agreeable. Furthermore, this reduces the load on the air conditioning for the shop floor, and thus the costs for discharge of the waste air. Regarding noise emissions, similar benefits can be observed. Full thermal insulation of a cleaning machine reduces its operating noise by up to 9 per cent (8 dB(A)), resulting in a noticeably more quiet work environment for the operators.

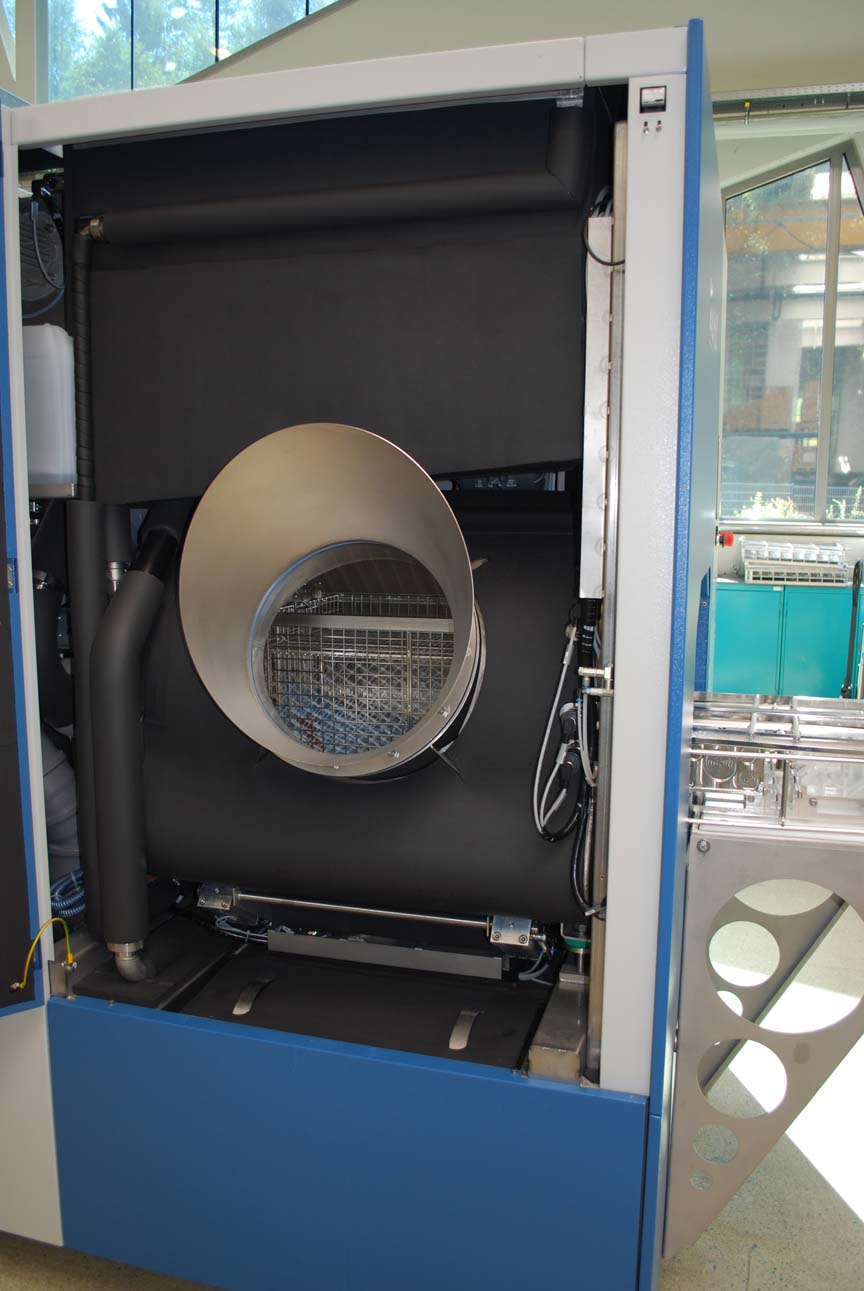

For research purposes in the frame of the ETA project, the compact cleaning machine MAFAC JAVA was equipped with full thermal insulation.

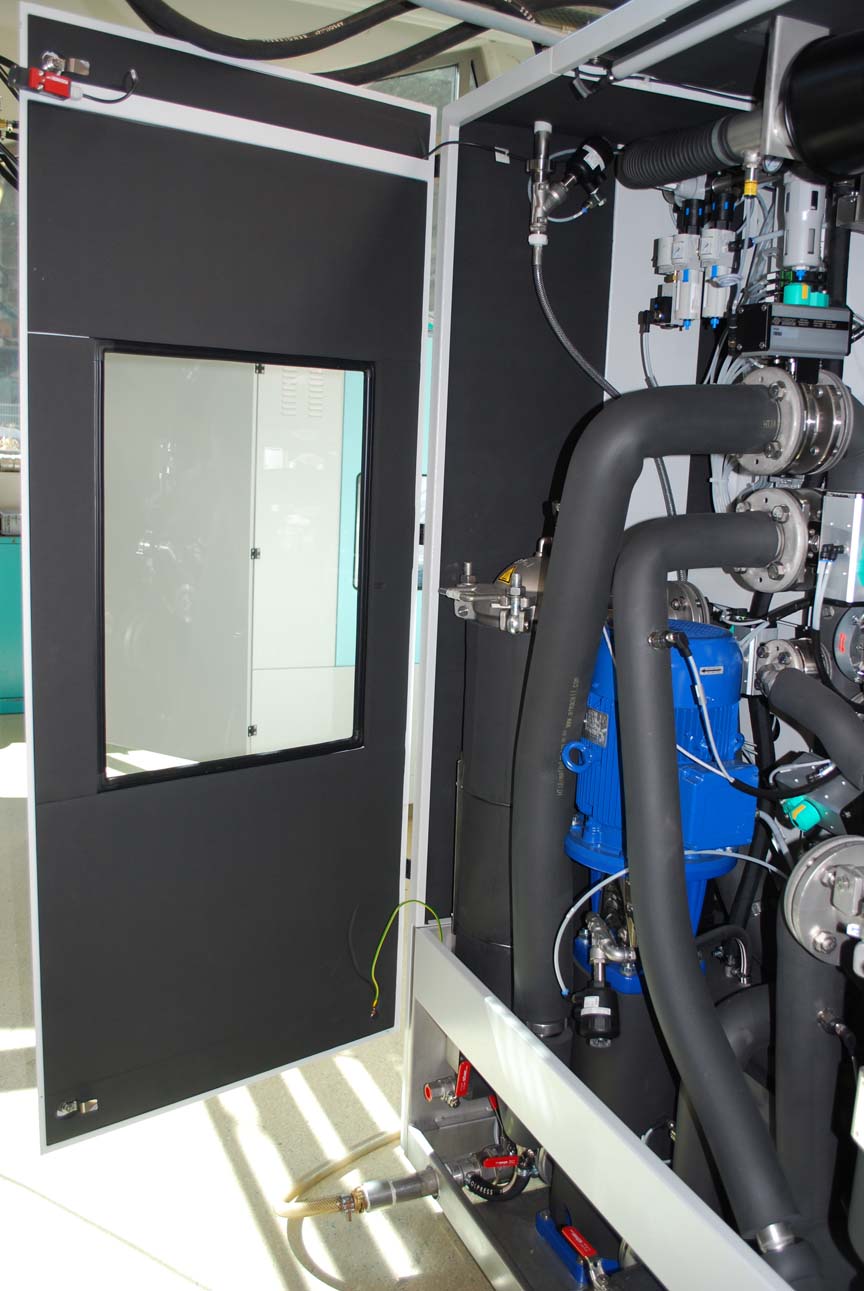

... and other elements of the machine infrastructure, for instance the flow ducts...

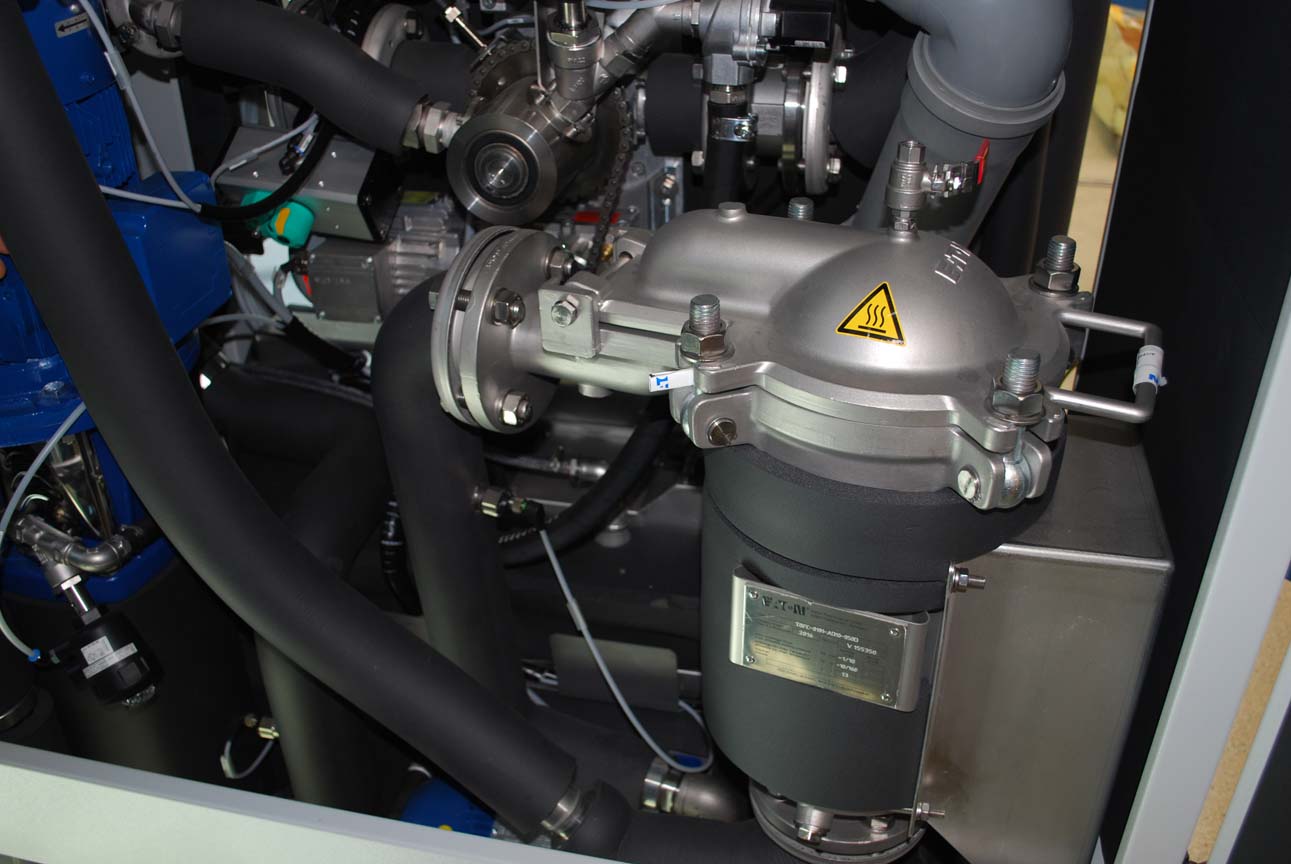

... and assemblies such as pump and filter housing as well as connection elements. Over 950 validated measuring tests showed that energy savings of 23 per cent can be achieved, compared to a machine without thermal insulation.